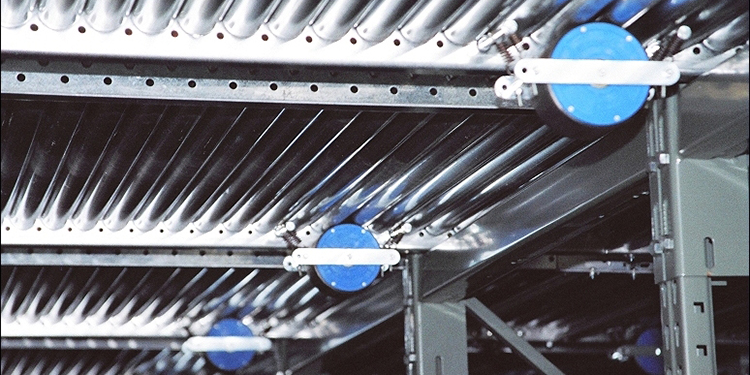

Learn How Converting Static Pallet Rack To Carton Flow Improves ...

With projections estimating that the North American e-commerce market will multiply at a compound annual growth rate (CAGR) of 12.5% between now and 2027, it is increasingly likely that facilities configured to primarily handle pallets will need to shift to ...

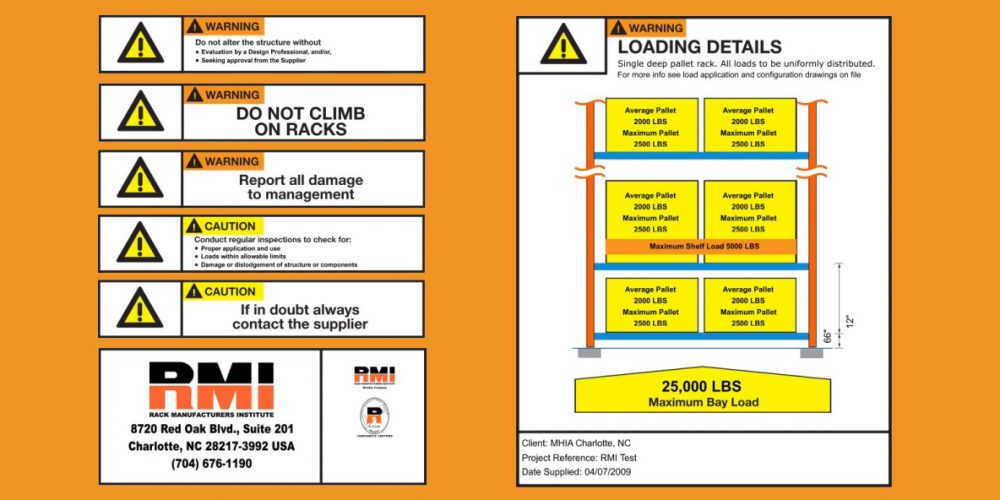

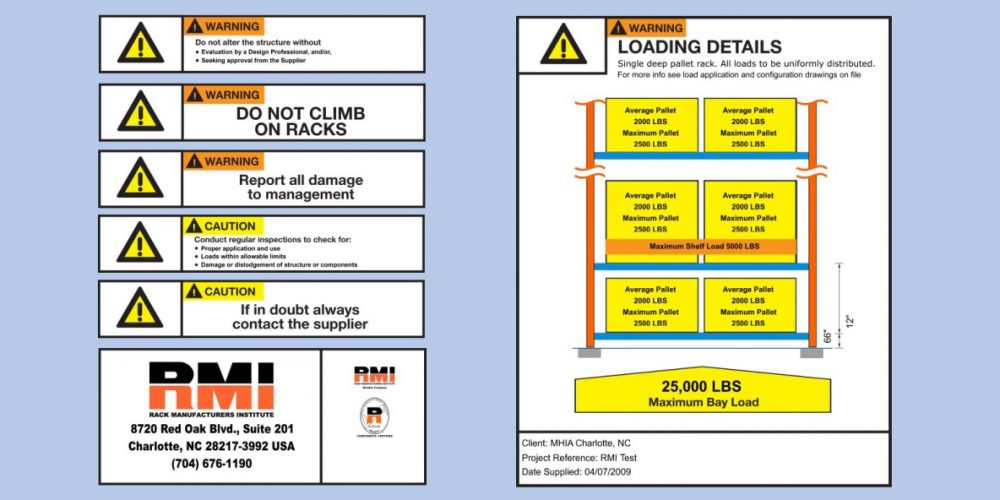

The Pros And Cons Of Labeling Load Capacities On Rack ...

Marking the maximum weight capacity on a pair of beams in a given pallet rack structure can be beneficial to an operation. After all, there are probably multiple labels and tags already adorning the faces of the beams to indicate ...

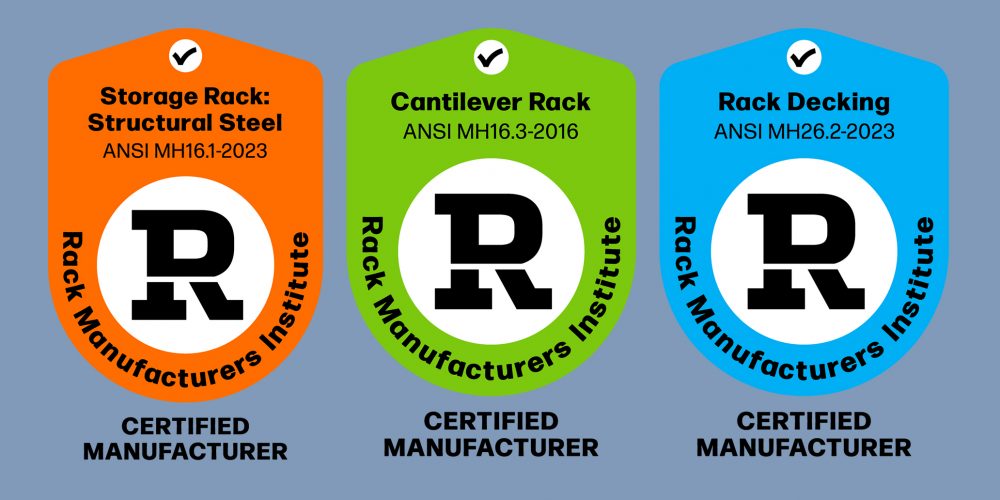

How Does R-Mark Certification Benefit Storage Rack And Decking Buyers?

The Rack Manufacturers Institute (RMI) recently revised and expanded its R-Mark® Certification program. Originally created in 1999, the voluntary program is for manufacturers of industrial steel storage racks and of rack decking. With the new revisions, R-Mark certification now applies ...

Rack Manufacturers Institute Updates R-Mark Certification Program

Established more than two decades ago, the Rack Manufacturers Institute’s (RMI) R-Mark® Certification program has been recently revised and expanded. While it remains a voluntary program for manufacturers of industrial steel storage racks and of storage rack decking, R-Mark certification ...

Why Storage Rack Load Capacity Plaques Are Important To The ...

When you install pallet racking in your facility, every inch of it comes designed specifically to meet local building codes for your configurations and loads. From the height of the materials to the spacing between pallets, the seismic rating, and ...

Why Pallet Rack LARC Drawings Are Important

Although industrial steel storage rack is designed and engineered with adjustable beams to accommodate different load heights, for safety never change the configuration without consulting the pallet rack LARC drawings and a qualified design professional first. LARC is an abbreviation ...

Nine Benefits Of Rack Repair Kits

Pallet rack damage happens, often due to an impact from a forklift as it transports a load through the facility. Upon identification of a damaged rack section the structure should be isolated, and a qualified, professional rack engineer should be ...

Load Plaques: Why Your Rack Installation Needs Them

When industrial steel storage rack installations have stamped and sealed engineering documents or load application and rack configuration (LARC) drawings, they should be kept on-site within the facility. These documents include critical details about the maximum safe capacity of the ...

How Picker Ergonomics Is Improved By Utilizing Pallet Separators In ...

Engineered to hold multiple pallet loads in individual lanes pitched downward, high-density pallet flow (or “gravity flow”) rack is frequently used in case-picking operations. In these systems, full pallets of product are loaded from the back (or “charging”) end and ...

Safeguard Rack Columns Against Forklift Impacts With These Five Protective ...

To help protect rack columns from forklift and other vehicle impacts, there are a number of optional rack guard accessories that can be added to aisle-side or end-facing rack columns (or to the floor in front of them). Additionally, for ...