How Does R-Mark Certification Benefit Storage Rack And Decking Buyers?

The Rack Manufacturers Institute (RMI) recently revised and expanded its R-Mark® Certification program. Originally created in 1999, the voluntary program is for manufacturers of industrial steel storage racks and of rack decking. With the new revisions, R-Mark certification now applies separately to manufacturers, their individual systems, and the installation of those systems. You may be wondering, however, how does R-Mark certification benefit storage rack and decking buyers?

The Rack Manufacturers Institute (RMI) recently revised and expanded its R-Mark® Certification program. Originally created in 1999, the voluntary program is for manufacturers of industrial steel storage racks and of rack decking. With the new revisions, R-Mark certification now applies separately to manufacturers, their individual systems, and the installation of those systems. You may be wondering, however, how does R-Mark certification benefit storage rack and decking buyers?

The answer, explained John Krummell, President and CEO of RMI member Advance Storage Products, is increased confidence in system safety.

“Only industrial steel storage rack and decking manufacturers who pass a stringent review process receive an R-Mark certification,” he said. “The review, conducted by an independent, professional rack engineer, confirms that the manufacturer has the ability to design design and build rack systems that meet RMI standards.”

RMI Standards Define Requirements for Safe Rack and Decking

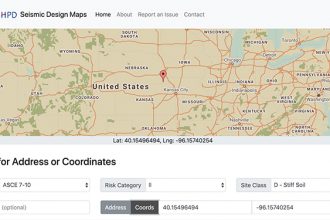

As part of its mission to promote the safe and effective use of industrial steel storage racks and related storage and handling systems, RMI publishes American National Standards Institute (ANSI) standards. These include:

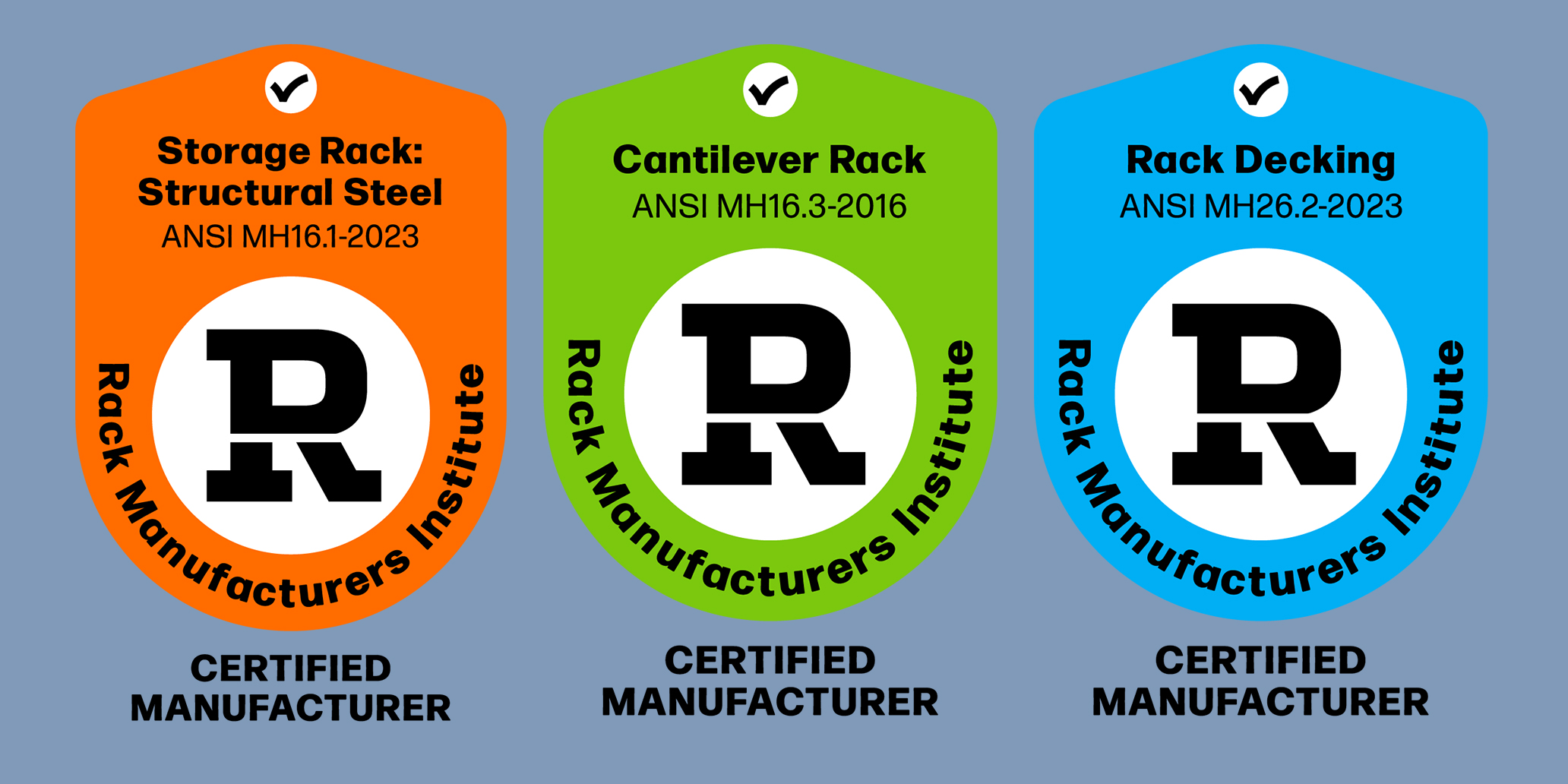

- ANSI MH16.1: Design, Testing, and Utilization of Industrial Steel Storage Racks, referenced by the International Building Code (IBC) as the standard for safe design and installation of steel storage racks

- ANSI MH16.3: Design, Testing, and Utilization of Industrial Steel Cantilevered Storage Racks

- ANSI MH26.2: Design, Testing, and Utilization of Industrial Steel Rack Decking

The standards establish requirements for the safe design, engineering, testing, installation, and inspection of storage rack and decking. RMI members collaborate to author and routinely update these standards. This ensures that rack engineers apply the most up-to-date calculation methodologies when designing rack components and unique systems.

R-Mark Certification Confirms Manufacturers Apply RMI Standards

To receive an R-Mark Certification manufacturers must submit a comprehensive application to RMI. The application is reviewed by an experienced professional engineer with extensive rack industry experience. The application details how the manufacturer meets applicable RMI standards in its design, engineering, and manufacturing processes.

Each application includes an engineering design and test data package with documents, sample test reports, and calculations. These demonstrate that the manufacturer’s systems, components, materials, and manufacturing processes conform to applicable RMI standards. If applicable, the manufacturer must submit separate test data packages for each type of product they offer. This includes roll formed steel rack, structural steel rack, cantilever rack, or rack decking.

Further, the manufacturer must include a sample calculation package to demonstrate an understanding of system design capabilities that comply with applicable RMI standards. Also required are documentation of:

- Product and production facility quality assurance and quality control processes across all facilities owned by the manufacturer;

- Steel integrity and consistency;

- Standards for product integrity;

- Compliance with welding standards from the American Welding Society; and

- Manufacturing certifications issued by local or regional municipalities.

An experienced licensed professional engineer with expertise in storage rack systems evaluates the manufacturer’s application and supporting documentation. If he or she finds that the submissions align with the applicable RMI standards, RMI issues a unique R-Mark certification number and license to the manufacturer.

To maintain their status, R-Mark Certified Manufacturers must submit an affirmation of continued compliance with the program’s requirements annually.

What Can and Can’t Be R-Mark Certified?

A manufacturer, a specific system, and an installation can each receive R-Mark certification. R-Mark certified manufacturers can only display, market, and use the specific mark they receive.

The R-Mark certification program is open to all manufacturers, added Krummell. “That includes companies who are not RMI members, as long as they complete the application process and certify that they will adhere to applicable RMI standards for all systems that bear the R-Mark,” he explained.

Upon receipt of their R-Mark Certified Manufacturer status, they can apply an R-Mark Certified System mark to a specific system designed and engineered in accordance with the applicable RMI standards. The R-Mark Certified System logo appears on manufacturer approved and stamped load application and rack configuration (LARC) drawings and load capacity plaques specific to the installation site.

Further, an R-Mark certified manufacturer can apply an R-Mark Certified Installation mark to an R-Mark Certified System after its installation is complete. The installation must pass an evaluation by a qualified inspector, working under the guidance of the engineer of record, to confirm the LARC drawings accurately reflect the installed storage rack system.

The R-Mark cannot appear on individual rack components, with the exception of rack decking. “Additionally, companies that only distribute, resell, and/or repair storage rack systems or components are not eligible for the program and cannot use the R-Mark,” added Krummell.

How to Find an R-Mark Certified Manufacturer

The current listing of R-Mark certified manufacturers is here. For more information about the R-Mark certification program and its benefit to storage rack and decking buyers, visit RMI’s website.