Rack Design Best Practices For Food Storage

No two rack designs are alike. That statement is particularly true for warehouses and distribution centers handling food. For safe and efficient storage of perishables, shelf-ready, or frozen products, the design, layout, construction, and finish of pallet rack must meet ...

Rack Safety Nets And Panels Stop Products From Falling, Part ...

As detailed in a previous post, rack netting and steel mesh containment panels mitigate the forces of gravity. Installed directly on the rack, these protective guarding solutions catch items that tumble from the upper levels of pallet rack. This reduces ...

Rack Safety Nets And Panels Stop Products From Falling, Part ...

Industrial steel storage rack is a great solution for maximizing overhead usable space in warehouses and distribution centers. But, thanks to gravity, storing items above floor level increases the risk of products tumbling to the ground. In addition to inventory ...

Seismic Considerations For Rack Designs Explored In New RMI Video

Rack safety is critical regardless of a facility’s geographic location. However, depending on the potential for earthquakes in a given region — as well as local building codes — a safe industrial steel storage rack installation may require more stringent ...

Examine These 9 Components During A Rack Safety Inspection

To ensure the safety and reliability of an industrial steel storage rack system, it is essential to perform routine inspections. These inspections, frequently conducted by warehouse employees or supervisors, are a visual assessment of the rack’s condition. To minimize the ...

Key Elements Of An Effective Warehouse Rack Safety Program

According to the National Safety Council (NSC), in 2021 workers in warehousing and transportation experienced the highest injury rate involving days away from work. To reduce those numbers and keep their employees safer on the job, many companies are continuously ...

Rack Installation Safety Requirements Detailed In RMI’s New Video

To ensure a safe workplace, it’s important to observe multiple precautions before, during, and after the implementation of a new industrial steel storage rack structure. However, facility owners and operations managers are often unfamiliar with these considerations. For that reason, ...

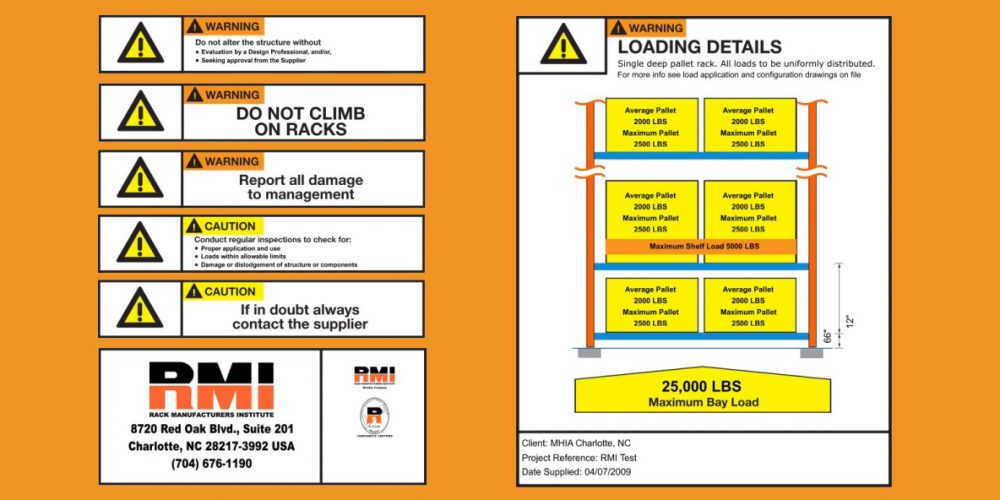

The Pros And Cons Of Labeling Load Capacities On Rack ...

Marking the maximum weight capacity on a pair of beams in a given pallet rack structure can be beneficial to an operation. After all, there are probably multiple labels and tags already adorning the faces of the beams to indicate ...

New Employee Training: Teaching The Basics Of Rack Inspection

To ensure the safety of personnel working in and around industrial steel storage rack, it is important to train new (and existing) employees on the basics of rack inspection. There are several areas that associates and forklift operators can assess ...

Why Storage Rack Load Capacity Plaques Are Important To The ...

When you install pallet racking in your facility, every inch of it comes designed specifically to meet local building codes for your configurations and loads. From the height of the materials to the spacing between pallets, the seismic rating, and ...