Rack Installation Safety Requirements Detailed In RMI’s New Video

To ensure a safe workplace, it’s important to observe multiple precautions before, during, and after the implementation of a new industrial steel storage rack structure. However, facility owners and operations managers are often unfamiliar with these considerations. For that reason, the members of the Rack Manufacturers Institute (RMI) have produced and released a new educational video. Running approximately five minutes long, the video details rack installation safety requirements across several different areas.

Site Survey and Assessment

The first rack installation safety requirements focus on the facility itself. Owners should conduct a site survey to ensure adequate fire protection and proper positioning of sprinkler systems in the rack’s planned location.

The video further advises an assessment of any structural obstacles — either wall- or floor-mounted — that might impede the rack’s installation. Facility operators should verify that all electrical work is complete as well.

Further, it’s important to determine that the floor or concrete slab will support the rack and its load. The floor must be level — as well as strong and thick enough — for a safe installation of the rack structure. The building’s engineer of record should have detailed documentation regarding both slab capacity and condition.

Permits and Licenses

Nearly every jurisdiction in the U.S. requires a review of a pallet rack system’s design drawings and a permit prior to its installation. That’s because most states, counties, and municipalities have adopted the International Code Council’s International Building Code (IBC). This code references RMI’s ANSI MHI16.1: Design, Testing, and Utilization of Industrial Storage Racks. That means pallet rack is part of every area’s building code requirements.

Additionally, installers should possess both a license from the state as well as insurance. It’s important to confirm this rack installation safety requirement prior to hiring the installers.

Construction Accommodations

As with all construction projects, it’s critical to remove any impediments to progress. In the case of facilities currently in use, the addition of new racking will require accommodations to ensure the safety and productivity of employees. Be sure they receive proper safety training for working in the vicinity of a construction site. Employees should also work well outside of the rack installation area, the staging zone for the structure’s components, and the ingress and egress areas used by the installers.

Rack Engineering Drawings

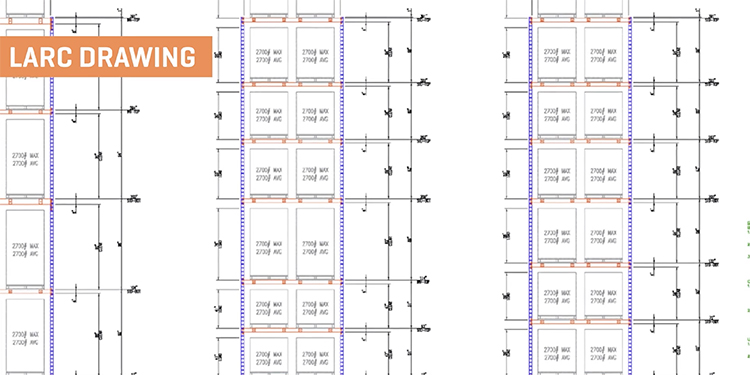

Another important rack installation safety requirement is for the installers to follow the supplied load application and rack configuration (LARC) drawings. Created and supplied by the rack’s engineer, these drawings detail the location, configuration, and capacity of the planned system. They also illustrate approved beam configuration options and the load capacities that each version can support safely.

Furthermore, the LARC drawings will identify the optimal anchoring approach. To ensure the structure’s stability during the installation, all components must be properly secured and tightened progressively.

Installers and OSHA Compliance

In addition to carrying proper licenses and insurance, installers must follow the Occupational Safety and Health Administration’s (OSHA) rack installation safety requirements. OSHA Standard 1910.140: Personal Fall Protection Systems applies to all crew members working at a 6-foot or higher elevation. The standard mandates that installers must use body harnesses, double-tied lanyards, and connections secured to areas that can withstand the force of a fall.

For rack installations, crews typically secure the tie-offs around a column just above a beam connection. Alternately, they can position the tie-offs around a column where it connects to a cross-aisle tie. A qualified engineer should approve these tie-off points for maximum safety.

Inspections Post-Installation

Upon completion of the rack installation, a final inspection should occur prior to loading. This inspection verifies that the entire rack configuration follows the LARC drawings. It also confirms that beams are at the proper elevation, columns anchors are secure, and all components are straight and plumb. As part of the permitting process, the local building inspector will require this inspection prior to issuing the final permit.

Once the rack is in use, owners should perform periodic rack inspections to further ensure the safety of their system. RMI offers a rack installation and safety inspection video to help in determining the frequency of these assessments.

Watch the Video

Want to Learn More About Rack Installation Safety Requirements?

RMI offers multiple resources detailing both standards and best practices that enhance pallet rack safety. This includes presentations, publications, case studies, frequently asked questions, and an MHI Cast podcast. The Rack Installation Safety Requirements video is part of a series. All of RMI’s industrial steel storage rack safety videos are available on its Rack Safety Blog or website.