Safeguard Personnel On An Industrial Work Platform With Protective Guarding, ...

Whether it’s called an industrial work platform, mezzanine, pick module, or rack supported platform, an additional level (or multiple levels) increases an operation’s usable space. It can also, however, increase an employee’s risk of injury due to a fall. Fortunately, ...

Safeguard Personnel On An Industrial Work Platform With Protective Guarding, ...

With the addition of an industrial work platform, an operation can gain valuable square footage without expanding the building’s footprint. However, associates accessing and working on these elevated areas are at an increased risk of injury from falls. Therefore, protective ...

Learn About Storage Rack Safety And Automation Integration At MODEX ...

Have questions about the safe design and use of pallet rack? Wondering how to successfully integrate industrial racking with automation? Answers to both questions can be found in two separate MODEX on-floor education sessions. Participating attendees will learn about both ...

People And Pallet Rack: Safety And Signage Best Practices

With more than 9.1 billion square feet of warehousing space in the U.S., pallet rack is everywhere. That pervasiveness, however, means that personnel could easily take its safety and reliability for granted. Therefore, owners and operators of warehouses and distribution ...

Relocating Pallet Rack To A New Facility? Read This First, ...

The previous post outlined three key areas a rack owner should consider prior to moving a storage rack system from one building to another. These include building codes, seismic activity, and fire suppression. There are, however, several other considerations to ...

Relocating Pallet Rack To A New Facility? Read This First, ...

Because storage racks are comprised of beams and uprights that can be reconfigured — and because each system represents a significant investment — free-standing pallet racks appear easy to relocate. That is, if an operation is moving from one address ...

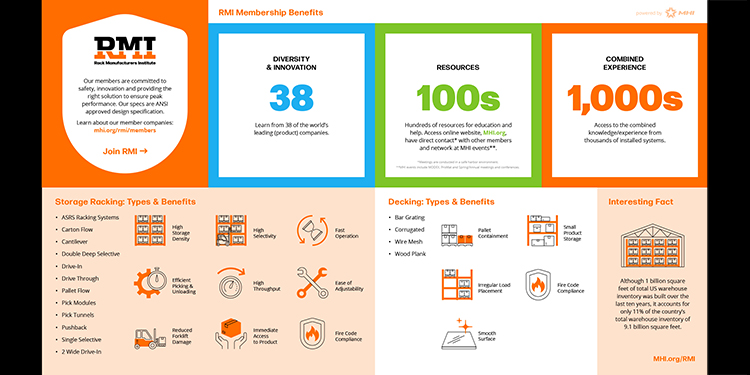

Rack Manufacturers Institute Unveils New Storage Racking And Decking Infographic

With members representing the industry’s leading suppliers of industrial steel storage racks and related structural systems, the Rack Manufacturers Institute is the leading authority on pallet rack and rack decking. Also known as RMI, the organization formed in 1958. Its ...

The Pros And Cons Of Labeling Load Capacities On Rack ...

Marking the maximum weight capacity on a pair of beams in a given pallet rack structure can be beneficial to an operation. After all, there are probably multiple labels and tags already adorning the faces of the beams to indicate ...

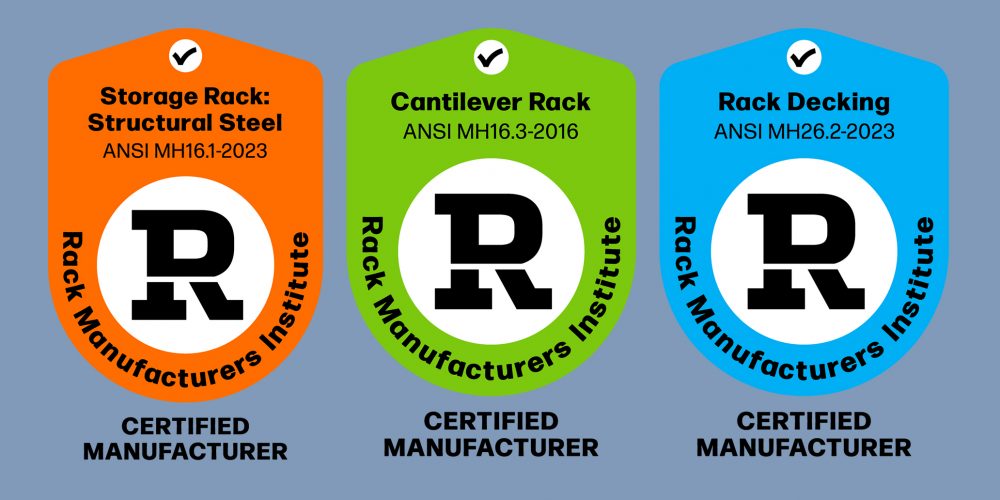

How Does R-Mark Certification Benefit Storage Rack And Decking Buyers?

The Rack Manufacturers Institute (RMI) recently revised and expanded its R-Mark® Certification program. Originally created in 1999, the voluntary program is for manufacturers of industrial steel storage racks and of rack decking. With the new revisions, R-Mark certification now applies ...

Rack Manufacturers Institute Updates R-Mark Certification Program

Established more than two decades ago, the Rack Manufacturers Institute’s (RMI) R-Mark® Certification program has been recently revised and expanded. While it remains a voluntary program for manufacturers of industrial steel storage racks and of storage rack decking, R-Mark certification ...