Rack Manufacturers Institute Unveils New Storage Racking And Decking Infographic

With members representing the industry’s leading suppliers of industrial steel storage racks and related structural systems, the Rack Manufacturers Institute is the leading authority on pallet rack and rack decking. Also known as RMI, the organization formed in 1958. Its leadership recently unveiled a new logo and a new storage racking and decking infographic.

The updated branding for the organization coincides with the recently revised R-Mark Certification program. That program also received a fresh, updated look, along with expanded parameters and revised requirements, said Paul Neal, President and CEO of RMI member UNARCO Material Handling. Neal also currently serves as RMI President.

“Aside from freshening up the Rack Manufacturers Institute brand on RMI’s 65th anniversary, the timing was optimal,” he explained. “Several of our publications received revisions and updates that are finalizing throughout 2023. It was a great opportunity to showcase a new look and highlight these latest standards and guidelines.”

Two ANSI Standards Revised for 2023

In keeping with its mission to promote the safe and effective use of industrial steel storage racks and related systems, the Rack Manufacturers Institute develops American National Standards Institute (ANSI) standards. The two revised standards for 2023 are:

- ANSI MH16.1: Design, Testing, and Utilization of Industrial Steel Storage Racks. This standard specifies the minimum requirements for the structural design, testing, and utilization of industrial steel storage racks. It applies to pallet racks, movable-shelf racks, rack-supported systems, and racks used with automated storage and retrieval systems (ASRS). Racks constructed of cold formed and/or hot-rolled steel structural members are covered. The International Building Code (IBC) references this document as the standard for safe design and installation of steel storage racks.

- ANSI MH26.2: Design, Testing, and Utilization of Industrial Storage Rack Decking. This standard provides a guideline for design, testing, fabrication, and utilization of industrial storage rack decking. Used as an accessory to pallet racks, decking rests on beams to create a surface for item placement. Decking types covered include welded-wire mesh with permanently attached reinforcements, metal bar grating, composite engineered wood, corrugated metal, perforated sheet metal, or other materials.

Both standards are available for purchase via mhi.org/rmi.

RMI Publishes Two Updated Guideline Documents in 2023

To help rack owners understand best practices when purchasing and repairing pallet rack, the Rack Manufacturers Institute publishes guideline documents. Two received content updates for 2023.

- Considerations for the Planning and Use of Industrial Steel Storage Racks. Written to provide guidance to warehouse operators who do not specialize in the technical, engineering, or design details, this guide offers insights into how to specify and utilize pallet racks.

- Guideline for the Assessment and Repair or Replacement of Damaged Rack. This document details best practices and considerations for repairing or replacing damaged racks. Its information targets owners, users, designers, purchasers and/or specifiers of repairs to racks and rack systems.

Both guideline documents are available for purchase via mhi.org/rmi.

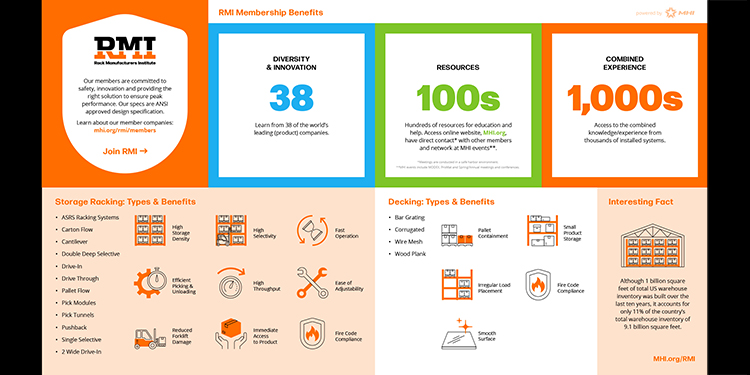

New Infographic Highlights Racking and Decking Types, Benefits

The new RMI infographic outlines the resources available for both members of the organization and users of industrial steel storage racks. It also lists the 12 primary types of storage racking represented by RMI members, including:

- ASRS Racking Systems

- Carton Flow

- Cantilever

- Double-Deep Selective

- Drive-In

- Double-Wide Drive-In

- Drive-Through

- Pallet Flow

- Pick Modules

- Pick Tunnels

- Pushback

- Single Selective

The infographic also details nine benefits of pallet rack:

- High storage density

- High selectivity

- Fast operation

- Efficient picking and unloading

- High throughput

- Ease of adjustability

- Reduced forklift damage

- Immediate access to product

- Fire code compliance

Further, the graphic highlights four types of rack decking:

- Bar Grating

- Corrugated

- Wire Mesh

- Wood Plank

The benefits associated with decking include pallet containment; small product storage; irregular load placement; fire code compliance; and smooth surface.

Want your own copy of the RMI Rack Safety Infographic? It’s available as a free download, here.