Over-The-Dock Racking: Special Considerations For Busy Loading Zones

When it comes to optimizing space in a warehouse, distribution center, or production facility, safety should always be the top priority. One often overlooked area that can provide a cost-effective solution for the need for additional storage is above the ...

People And Pallet Rack: Safety And Signage Best Practices

With more than 9.1 billion square feet of warehousing space in the U.S., pallet rack is everywhere. That pervasiveness, however, means that personnel could easily take its safety and reliability for granted. Therefore, owners and operators of warehouses and distribution ...

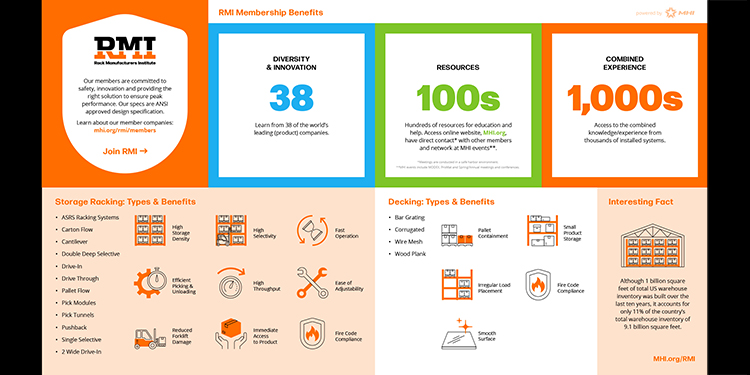

Rack Manufacturers Institute Unveils New Storage Racking And Decking Infographic

With members representing the industry’s leading suppliers of industrial steel storage racks and related structural systems, the Rack Manufacturers Institute is the leading authority on pallet rack and rack decking. Also known as RMI, the organization formed in 1958. Its ...

Rack Manufacturers Institute Debuts New Logo To Celebrate 65th Anniversary

Founded in 1958, the Rack Manufacturers Institute (RMI) is an MHI Industry Group and the leading racking industry association. Currently comprised of 38 members who are the industry’s top suppliers of industrial steel storage racks and related structural systems, RMI ...

The Six Different Rack Safety Inspections Needed During A System’s ...

To ensure the safety and performance of a rack system, a series of six separate inspections is conducted throughout the system’s lifetime. An MHI Cast podcast recording about rack safety discusses the different types of inspections. It features the late ...

Nine Benefits Of Rack Repair Kits

Pallet rack damage happens, often due to an impact from a forklift as it transports a load through the facility. Upon identification of a damaged rack section the structure should be isolated, and a qualified, professional rack engineer should be ...

Rack Safety, Design Pivotal In Growth Of MHI’s Oldest Industry ...

This article by Stephen Murdock originally appeared in the fourth quarter 2020 issue of MHI Solutions magazine and has been reprinted in its entirety with permission. The Rack Manufacturers Institute (RMI), officially the oldest Industry Group in MHI, has seen ...

The “Dos And Don’ts” Of Rack Ownership

Whether you own an industrial steel storage rack system — or are considering investing in one — ownership comes with a variety of responsibilities. These include ensuring the structure is in compliance with applicable standards and properly maintained for the ...

Rack Inspections 101: Guidelines Ensure Safety, Productivity

Conducting periodic rack inspections to verify that a facility’s industrial steel storage rack complies with applicable standards are not only recommended by RMI, they’re also the best way to ensure the safety and performance of the system. Both American National ...

Rack Repair Kits: What You Need To Know

When a damaged rack section is assessed by a qualified, professional rack engineer, it may be determined that a repair can be completed with a rack repair kit as opposed to field welding. That’s because, as outlined in Appendix 1 ...