Integrating Automation And Pallet Racks? Follow These Design Recommendations For ...

As anyone who attended MHI’s MODEX 2024 this past March can attest, warehouses, distribution centers, and fulfillment operations increasingly incorporate automated equipment. Many also utilize industrial steel storage rack within their facilities. Depending on the application, automation and pallet racks ...

Review Storage Rack Safety Basics In Recording Of RMI’s MODEX ...

At MODEX 2024, members of the Rack Manufacturers Institute (RMI) shared “Pallet Rack Safety 101,” a 35-minute presentation. The session detailed why the safe use of an industrial storage rack system is key to warehouse productivity. For those who either ...

Key Takeaways From RMI’s MODEX 2024 Pallet Racking And Automation ...

While most warehousing and distribution facilities have industrial steel storage rack systems, far fewer have automated equipment. However, as workforce availability continues to be a challenge, operations are increasingly assessing automated solutions. “Pallet Racking Systems and Design for an Automated ...

Smart Pallets And Racking: What Rack Owners Need To Know ...

Companies worldwide are increasingly implementing Internet of Things (IoT) technologies across assets, equipment, and machinery. Pallets, both plastic and wooden, are part of that trend. IoT-enabled pallets sport various sensors to monitor temperature, humidity, pressure, acceleration, and location. These tracking ...

Mobile Automated Vehicles, Pallet Rack Selection, And Design

Advances in mobile automated vehicle technology is making the practicality of deploying them in warehouses and distribution centers more feasible. These solutions include autonomous mobile robots (AMRs), automatic guided vehicles (AGVs), and self-driving forklifts. Indeed, forecasts predict the market for ...

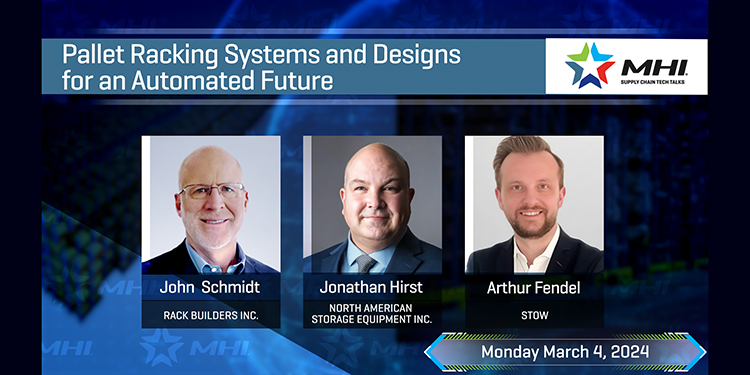

March 4 MHI Tech Talk Explores Integrating Racks With Automation

Pallet racking systems are virtually ubiquitous in warehouses, distribution centers, and fulfillment operations worldwide. Automation, on the other hand, is less so. Yet, with the persistent shortage of available workers, more of these facilities are evaluating automated solutions. Prior to ...

Learn About Storage Rack Safety And Automation Integration At MODEX ...

Have questions about the safe design and use of pallet rack? Wondering how to successfully integrate industrial racking with automation? Answers to both questions can be found in two separate MODEX on-floor education sessions. Participating attendees will learn about both ...

Don’t Miss The Latest Rack Safety Solutions At MODEX 2024

Atlanta’s Georgia World Congress Center will host more than 900 exhibitors at MODEX this year — March 11-14, 2024. That’s a lot of material handling equipment to explore! If you’re specifically looking for new rack safety products, however, be sure ...

RMI Scholarships Support The Future Of Rack Design, Use

Annually, the members of the Rack Manufacturers Institute (RMI) sponsor academic scholarships as part of the Material Handling Education Foundation, Inc. (MHEFI). RMI’s scholarships support undergraduates who represent the future of rack design, engineering, and use. RMI offers these scholarships ...

New Employee Training: Teaching The Basics Of Rack Inspection

To ensure the safety of personnel working in and around industrial steel storage rack, it is important to train new (and existing) employees on the basics of rack inspection. There are several areas that associates and forklift operators can assess ...