RMI Requests Volunteers To Approve Updated Storage Rack Standard

The Rack Manufacturers Institute (RMI) is proposing revisions to the American National Standard for industrial storage racks, ANSI MH16.1-2012(R2019), and requests volunteers to serve on an approval committee to review and approve the revised standard. Individuals interested in participating on ...

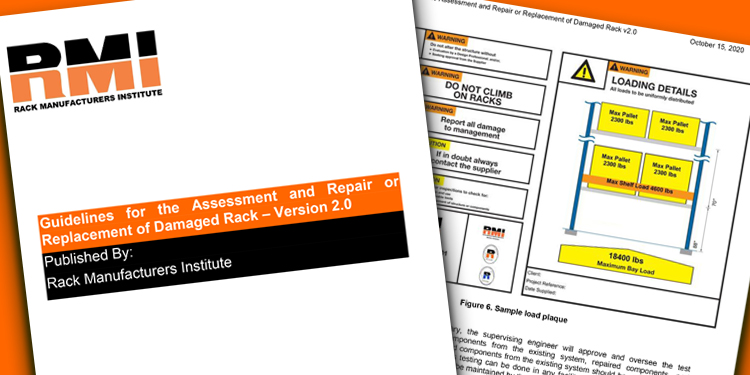

Updated Rack Repair Guidelines Released by RMI

The Rack Manufacturers Institute (RMI) has updated its existing publication, Guidelines for the Assessment and Repair or Replacement of Damaged Rack, with the latest information as a reference for owners and users of industrial pallet rack systems. The latest release, ...

Sticker Shocker: Why Used Rack Is More Expensive Than You ...

Many warehouse and distribution center owners consider pallet storage rack to be a commodity; that is, all racks are created equal. Therefore, to save a few dollars, they might consider purchasing used pallet rack on the secondary market—because its less ...

Not All Steel Is Created Equal: Why R-Mark Certification Matters

Steel is steel is steel—right? Wrong. And making that assumption when evaluating potential rack suppliers could lead to a system failure if the manufacturer uses a steel formulation that is not compatible with its production equipment. Reputable industrial steel storage ...

Why Pallet Quality Is Key To Safe Rack Utilization

Although industrial storage rack systems are specifically designed and engineered to support a given type of pallet and load, simply placing the approved pallet into a storage position isn’t enough to ensure the safety of the structure and facility personnel. ...

The Importance Of Matching Pallets To Rack Type For Safe ...

Products arrive in warehouses and distribution centers on any number of pallet types these days: two-way entry, four-way entry, skids, slip-sheets, nine-block, and more. Some pallets are designed with multiple boards—or stringers—spanning the bottom surface; others have a foot in ...

Soil Classification And Its Importance To Safe Seismic Rack Design

A soil classification is assigned to a location based on the characteristics of the types of soils present, including the ability of the soil to withstand the weight of the structures built on it. Therefore, it’s important to have this ...

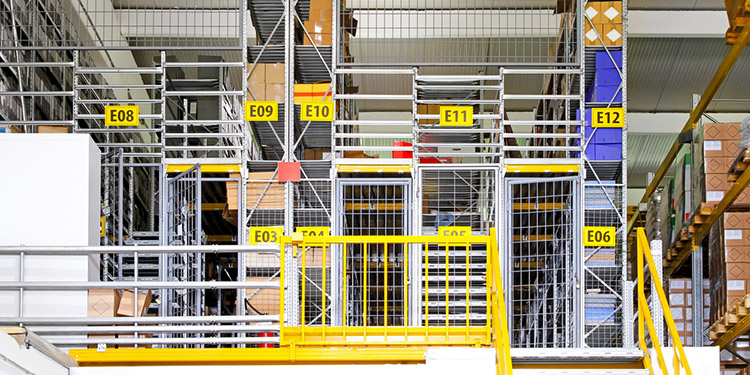

How Kickplates On Elevated Work Platforms Contribute To Worker Safety

Among the fall protection measures required for elevated work platforms, pick modules, or rack supported platforms—including guarding, stair handrails, and temporary access devices—kickplates are the one system that doesn’t protect associates working on the platform. Instead, they are often the ...

Load Handling And Elevated Work Platforms: How To Ensure Safe ...

To replenish pallets of product picked by associates working in pick modules or on rack supported platforms, most facilities use forklifts to deliver the loads to a pallet drop zone at an aisle-side ledge. While guardrails are required by the ...