How Does Seismic Design Affect Rack Systems?

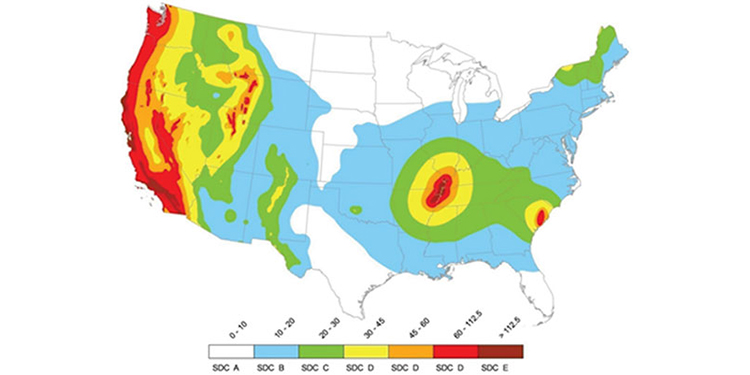

Seismically designed rack is not just on the West Coast anymore. Depending on where within the U.S. a facility is located, seismic design considerations may need to be taken into account when engineering, manufacturing and installing a pallet rack system. ...

What Is An R-Mark Certification And Why Is It Important?

RMI’s R-Mark Certification is a voluntary program for manufacturers of industrial steel storage racks and of welded wire rack decking. Certification assures storage rack users that the rack frame, beam and decking capacities shown in a unique design’s load table ...

Do These Four Things Before Reconfiguring Pallet Rack

With most pallet rack manufactured for adjustability and assembly in multiple configurations, an owner might think an existing installation can be safely reconfigured at will. For example, to increase storage density, why not convert five-beam racking to six by decreasing ...

Six Questions To Ask When Considering Buying Used Rack

A warehouse shuts down, and its assets and fixtures are sold—including the pallet storage rack, which is now available on the secondary, or used, market at a discount over a new system. While the perceived cost savings might seem to ...

Why Are Load Capacity Plaques Important?

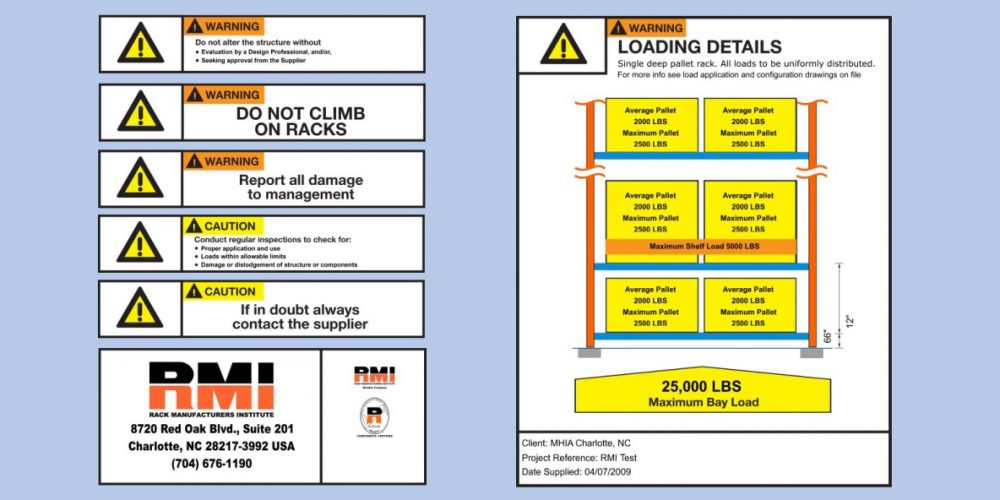

Regardless of when a steel storage rack installation was designed, commissioned and installed, the original stamped and sealed engineering documentation detailing the maximum safe rack capacity should be kept on-site within a facility. However, chances are that paperwork is likely ...