The Basics Of Safe Guardrails For Elevated Work Platforms

To maximize the overhead space in their facilities, many operations utilize elevated work platforms, pick modules, or rack supported platforms upon which workers access stored items. Because they’re working above ground level, it’s important to integrate permanent fall protection—specifically guardrails—around ...

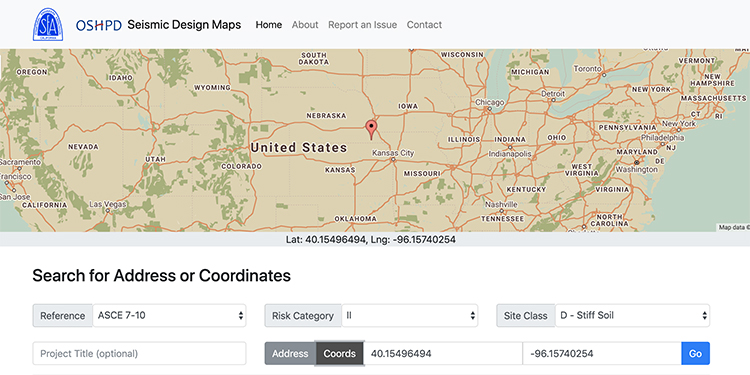

Will Your Rack Design Require A Seismic Force Review?

It’s a common misconception that seismically designed rack is only found west of the continental divide. In fact, earthquake activity has been documented in multiple regions throughout the U.S., including the Midwest and Southeast. That’s why, depending on where within ...

Safety Specifications For Pick Module Stair Design

Associates working within pick modules or on rack supported platforms to retrieve items stored above the facility floor access those higher levels via stairways. Protecting those workers from falls is, therefore, of critical importance. For that reason, the safe design ...

Rack Inspections: An Overview

Among the many best practices to ensure the safety of industrial steel storage rack systems and the workers around it, inspections are among the most critical. Indeed, there are several kinds of rack inspections, including: Inspections Required By Building Codes: ...

Why It’s Safest To Work With A Qualified Rack Engineer

Throughout RMI’s two published guidelines—Considerations for the Planning and Use of Industrial Steel Storage Racks and Guideline for the Assessment and Repair or Replacement of Damaged Rack—repeated references are made about the importance of using a qualified, experienced industrial steel ...

Why Rack Systems Must Comply With Building Codes

Industrial steel storage rack owners are sometimes surprised to learn that the verification of the structure’s safety and design is governed by one or more local jurisdictions, such as state, county or local municipality. Additionally, this permitting and inspection process ...

Comprehensive Resources For Safe Rack Design, Use Detailed In RMI’s ...

The safe use of a storage rack system is key to the ongoing productivity of a warehousing operation. That’s why members of RMI will both share insights from the current standards for the design, testing and utilization of industrial steel ...

Rack System Enhancements That Further Mitigate Forklift Impacts

A previous blog entry reviewed a selection of optional guarding accessories. These add-ons are applied at the time of installation—or as a later retrofit—to aisle-side or end-facing rack columns (or to the floor in front of them) to minimize the ...

Point Versus Uniformly Distributed Loads: Understand The Difference

When placing loads of equal weight in storage racks, it’s important to remember that all pallets or loads are not created equal. Some pallets are designed with multiple boards—or stringers—spanning the bottom surface; others have a foot in each corner. ...