Updated Methodology for Seismic and Stability Calculations in Rack Designs ...

A previous post explored the changes in ANSI MH16.1-2023: Design, Testing, and Utilization of Industrial Steel Storage Racks specific to a recently updated methodology for performing seismic and stability calculations. These changes were part of rack design standard updates routinely made ...

Updated Methodology for Seismic and Stability Calculations in Rack Designs ...

Dedicated to continually improving the safety and performance of industrial steel storage racks, the members of the Rack Manufacturers Institute (RMI) routinely publish rack design standards. Among them is ANSI MH16.1-2023: Design, Testing, and Utilization of Industrial Steel Storage Racks, ...

Integrating Automation And Pallet Racks? Follow These Design Recommendations For ...

As anyone who attended MHI’s MODEX 2024 this past March can attest, warehouses, distribution centers, and fulfillment operations increasingly incorporate automated equipment. Many also utilize industrial steel storage rack within their facilities. Depending on the application, automation and pallet racks ...

Safeguard Personnel On An Industrial Work Platform With Protective Guarding, ...

Whether it’s called an industrial work platform, mezzanine, pick module, or rack supported platform, an additional level (or multiple levels) increases an operation’s usable space. It can also, however, increase an employee’s risk of injury due to a fall. Fortunately, ...

Safeguard Personnel On An Industrial Work Platform With Protective Guarding, ...

With the addition of an industrial work platform, an operation can gain valuable square footage without expanding the building’s footprint. However, associates accessing and working on these elevated areas are at an increased risk of injury from falls. Therefore, protective ...

Key Takeaways From RMI’s MODEX 2024 Pallet Racking And Automation ...

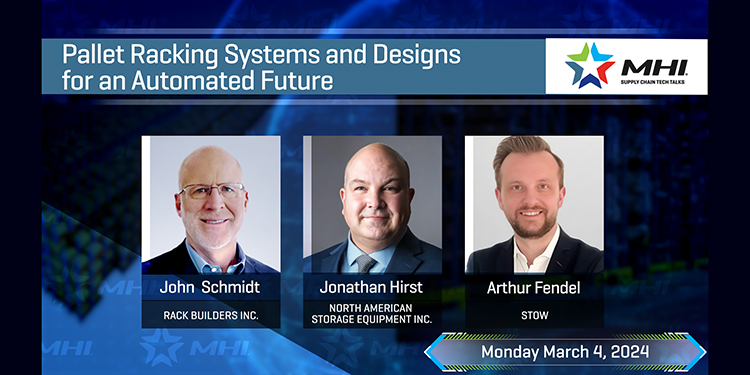

While most warehousing and distribution facilities have industrial steel storage rack systems, far fewer have automated equipment. However, as workforce availability continues to be a challenge, operations are increasingly assessing automated solutions. “Pallet Racking Systems and Design for an Automated ...

March 4 MHI Tech Talk Explores Integrating Racks With Automation

Pallet racking systems are virtually ubiquitous in warehouses, distribution centers, and fulfillment operations worldwide. Automation, on the other hand, is less so. Yet, with the persistent shortage of available workers, more of these facilities are evaluating automated solutions. Prior to ...

Learn About Storage Rack Safety And Automation Integration At MODEX ...

Have questions about the safe design and use of pallet rack? Wondering how to successfully integrate industrial racking with automation? Answers to both questions can be found in two separate MODEX on-floor education sessions. Participating attendees will learn about both ...

Don’t Miss The Latest Rack Safety Solutions At MODEX 2024

Atlanta’s Georgia World Congress Center will host more than 900 exhibitors at MODEX this year — March 11-14, 2024. That’s a lot of material handling equipment to explore! If you’re specifically looking for new rack safety products, however, be sure ...

Key Factors To Consider When Designing A Warehouse Rack Layout

Whether equipping a new distribution center (DC) or outfitting an expansion to an existing warehouse, it’s critical to get the pallet rack layout right before product is loaded into it. An incorrect layout might impede access to inventory or hinder ...