Why Pallet Rack LARC Drawings Are Important

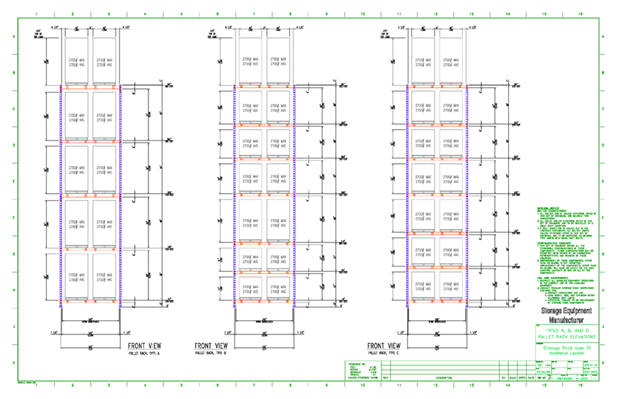

Although industrial steel storage rack is designed and engineered with adjustable beams to accommodate different load heights, for safety never change the configuration without consulting the pallet rack LARC drawings and a qualified design professional first. LARC is an abbreviation for load application and rack configuration. These drawings show the maximum loads and allowable beam elevations for which the specific system was designed. Original equipment manufacturers (OEMs) and approved resellers should provide a set of LARC drawings with every rack installation. These drawings include important information detailing the maximum safe storage capacity for the given racking structure. That’s why pallet rack LARC drawings are important.

Drawing Requirements

The use of and information included on pallet rack LARC drawings are outlined in RMI’s American National Standard ANSI MH16.1: Design, Testing and Utilization of Industrial Steel Storage Racks, section 4.6. The Occupational Safety and Health Administration (OSHA) relies on RMI and ANSI MH16.1 for the design, testing, and utilization of pallet rack, including LARC drawings. Additionally, ANSI MH16.1 is referenced by the International Code Council’s (ICC) International Building Code (IBC) as the standard for safe design and installation of pallet racks. Therefore, pallet rack LARC drawings are part of ensuring compliance with state, county, and local jurisdictions’ building codes.

How to Use Pallet Rack LARC Drawings

Should a facility’s pallet loads become shorter or taller, management may want to adjust the beam elevations from the current configuration to accommodate different load heights. For instance, consider a system with four levels of storage. To make more room for taller pallets at floor level, removing the lowest beam may seem like a convenient adjustment. However, the removal of that beam will alter the capacity of the entire system. That can increase the likelihood of loading the system beyond its design capacity.

Should a facility’s pallet loads become shorter or taller, management may want to adjust the beam elevations from the current configuration to accommodate different load heights. For instance, consider a system with four levels of storage. To make more room for taller pallets at floor level, removing the lowest beam may seem like a convenient adjustment. However, the removal of that beam will alter the capacity of the entire system. That can increase the likelihood of loading the system beyond its design capacity.

All rack OEMs and their approved resellers work with customers to evaluate both current and potential storage needs prior to designing the system. The pallet rack LARC drawings show all of the approved beam configurations, and the load capacities each can safely support. The drawings aid rack owners in both reconstructing the design process and understanding how changes might alter the rack’s loads and capacities.

Any alterations or adjustments to the rack system must use the same components and precisely match the drawing specifications indicated on the LARC drawings. Without the LARC drawings to refer to, reconfiguring the rack system could end in an overloaded and unsafe scenario.

Too often, warehouse operators don’t have the LARC drawings handy and just proceed with reconfiguration. It is essential to consult the drawings. Best practice is to consult with the OEM or engage a qualified, professional rack engineer to create updated LARC drawings, supported by structural calculations to verify the safety of proposed changes before making any adjustments to a system.

What to Do if a Desired Configuration Isn’t on the LARC Drawings

If the approved configuration options shown in the pallet rack LARC drawings do not match the desired changes, it is ideal to consult the OEM of the rack or their approved reseller. Alternately, engage a qualified, professional rack design engineer to re-evaluate the capacity of the system. If the new configuration is safe, the manufacturer or professional engineer will create an updated set of LARC drawings. Further, any significant modifications to the structure’s configuration that result in a load capacity change may require updated storage rack load capacity plaques.

LARCs Provide Traceability

Another reason for LARC drawings is traceability. The drawings will both inform and remind rack owners who the OEM was should they want to make configuration changes. Traceability also allows rack owners to know who made the system, what the original engineering package was — and if it remains unchanged. For example, think about the tires on a car. They have a specific set of information on the sidewalls that display how much air to put in them. Pallet rack LARC drawings are similar.

Repairs Require Updated Drawings

Repairs Require Updated Drawings

Additionally, after the repair of a damaged rack structure — ideally by the OEM — it is important to update the LARC drawings accordingly. These updates show the placement of the engineered repair kit(s) used. They also include details about the size of the replacement columns, position of splices, frame bracing, anchorage, and baseplate modifications. Additional details are in RMI’s Guidelines for the Assessment and Repair or Replacement of Damaged Rack, section 8.1.1.

Want more information about pallet rack LARC drawings? Purchase RMI’s ANSI MH16.1: Design, Testing and Utilization of Industrial Steel Storage Racks.