New Employee Training: Teaching The Basics Of Rack Safety

According to 2021 data from the U.S. Bureau of Labor Statistics (BLS), the average rate of recorded injuries among warehousing employees was 5.5 for every 100 full-time workers. That represented an increase of 23% (122,700 cases) of days away from work over the 99,800 cases in 2020. That’s why it is so important to train employees on how to correctly use and work with warehouse equipment, including the basics of rack safety.

According to 2021 data from the U.S. Bureau of Labor Statistics (BLS), the average rate of recorded injuries among warehousing employees was 5.5 for every 100 full-time workers. That represented an increase of 23% (122,700 cases) of days away from work over the 99,800 cases in 2020. That’s why it is so important to train employees on how to correctly use and work with warehouse equipment, including the basics of rack safety.

No matter what type of industrial steel storage rack a facility has—selective, drive-in, pushback, pallet flow, cantilevered, drive-thru, dual-bay, or other system—there are several basic safety practices. Section 5 of RMI’s Considerations for the Planning and Use of Industrial Steel Storage Racks outlines many of these recommendations, noted Jim Augustyniak, Regional Sales Manager at RMI member Steel King.

“Any employee who interfaces with a rack system as part of their job needs training on what is and isn’t a safe interaction with rack,” he said. “Primarily this means forklift drivers and order selectors or pickers who are walking aisles and filling orders. But everyone in the facility has a responsibility to alert managers or supervisors to unsafe situations. That’s why it’s important for all new employees to learn the basics of rack safety.”

Basics of Rack Safety #1: Safe Loading and Unloading of Rack

Teach employees operating forklifts how to properly load and unload pallet rack. This includes learning how to place the unit loads onto the beams so that the load does not fall. It also includes demonstrating how to remove loads from the rack without dislodging the beams.

Racks loading should always be from the bottom level upward whenever possible. Additionally, when placing loads in the rack, positioning should be as uniform and symmetrical as possible, Augustyniak explained.

“Manufacturers design pallet rack beams rated for uniformly distributed loads, meaning weight evenly spread over the entire beam length. Conversely, a point load is one with its weight significantly concentrated in one or more places on the rack’s beams,” he said.

Placing a point load within a rack designed to support uniformly distributed loads could cause excessive beam deflection (bowing) and/or system failure. “For example, even if the beams’ capacity rating is for 7,200 pounds, placing one 6,000-pound load in the middle creates a point load that could cause the beams to fail,” Augustyniak continued. “Train forklift operators to place two, 3,000-pound loads side-by-side in a storage bay to distribute the weight evenly.”

Basics of Rack Safety #2: Follow Load Plaque Guidance Prevent Rack Overloading

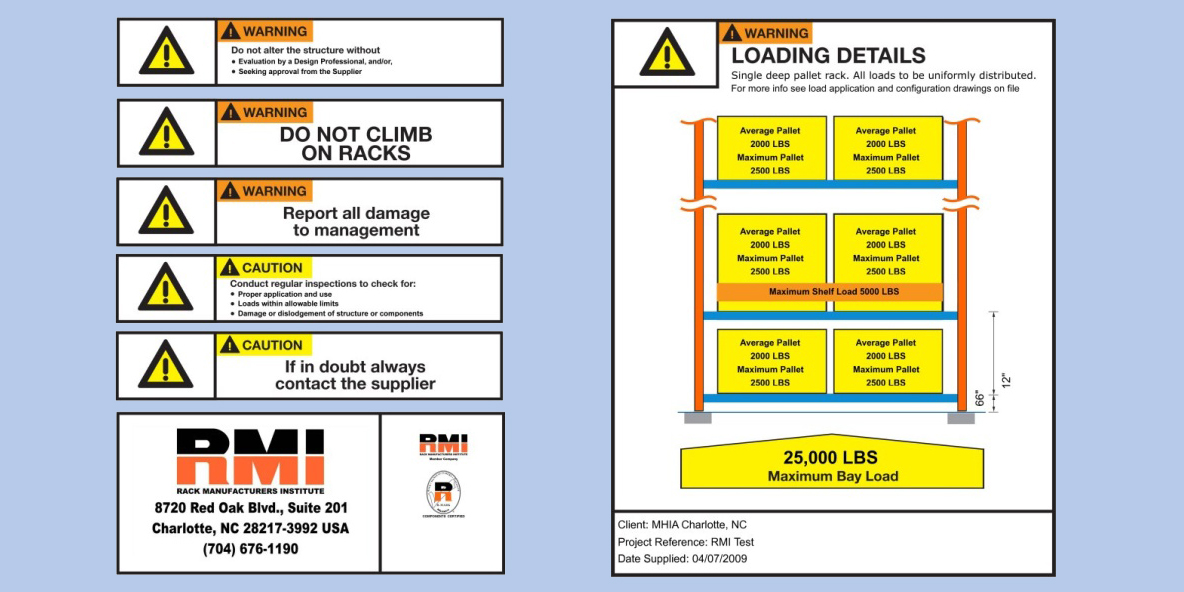

To help forklift operators easily see how to load a rack structure properly, point them to load capacity plaques mounted on or near the system. As mandated by RMI’s American National Standard ANSI MH16.1: Design, Testing and Utilization of Industrial Steel Storage Racks, load plaques must:

- Be a minimum of 50 square inches in size.

- Include the maximum permissible unit load (the combined weight of product and its storage container or pallet) and/or maximum uniformly distributed load per level.

- Detail the average unit load (calculated as the maximum total weight of product expected on all beam levels in any row, divided by the number of beam levels in that row), if applicable.

- Indicate the total actual loading expected in interconnected bays.

- Display the maximum total load per bay.

- Indicate which storage levels allow multiple stacking of unit loads.

Basics of Rack Safety #3: Avoid Impacts to Rack

Any rack impacted by a forklift is likely to sustain damage. Depending on how forceful the collision was, beams and column connections could become disengaged, anchor bolts loosened, columns bent, or the rack section could collapse. The damage may be difficult to spot, or clearly visible. Educate forklift operators to navigate through rack aisles and around corners with caution. Further, train them to avoid hitting the racks with the load, forks, or vehicle.

“Rack columns and beams are sometimes incorrectly used by forklift operators as a guiderail when placing a load into a rack,” observed Augustyniak. “Drivers will push the load against the rack structure to help them feel their way into proper position. This is a bad practice that will result in rack damage. Train drivers to place loads properly.”

Basics of Rack Safety #4: Report Rack Damage Immediately

Train and encourage both forklift drivers and other personnel to report any impacts or observed rack damage to managers or supervisors immediately.

“Not every employee feels comfortable admitting they hit a rack with a forklift. So, it’s important to create a culture where they can report an accident without fear of losing their job,” Augustyniak said. “Also, explain to other employees that if they see rack damage, they need to report it promptly. Then, rope off the area until the issue is addressed.”

Best practice is to have a policy or procedure in place for how to report rack damage when it occurs or upon discovery. It’s also important to routinely inspect rack for signs of damage. Inspection guidelines are detailed in RMI’s Considerations for the Planning and Use of Industrial Storage Racks. RMI’s Guideline for the Assessment and Repair or Replacement of Damaged Rack provides guidance on how to repair rack systems.

Basics of Rack Safety #5: Never Climb On or Into Rack

For their safety, pickers and other employees should never climb on or into a rack structure for any reason. Additionally, wire rack decking is not a suitable walking surface. Instead, provide poles with hooks to pull fallen product forward.

Should a pallet jam occur in pallet flow rack, use one of four techniques (plugging, force loading, adjacent lane clearing, or pick face loading) to resolve the issue. Likewise, to resolve a jam in a pushback rack, there are several recommended best practices—none of which require an operator to climb into the structure.