Load Plaques: Why Your Rack Installation Needs Them

When industrial steel storage rack installations have stamped and sealed engineering documents or load application and rack configuration (LARC) drawings, they should be kept on-site within the facility. These documents include critical details about the maximum safe capacity of the structure. However, because such documentation may not be on-site, or is stored in a filing cabinet and not easily accessible to operators and associates working with and maintaining the system, RMI’s ANSI MH16.1: Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks requires the application of one or more load plaques.

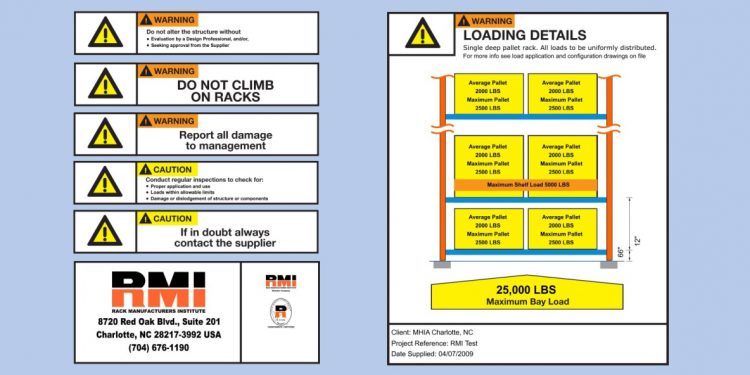

Intended to enhance the safety of the system and the personnel working around it, these load plaques must be displayed on or near the rack structure. ANSI MH16.1 sets forth the following requirements for the load plaques:

- They must be a minimum of 50 square inches in size.

- They must include the maximum permissible unit load (the combined weight of product and its storage container or pallet) and/or maximum uniformly distributed load per level.

- They must detail the average unit load (calculated as the maximum total weight of product expected on all beam levels in any row, divided by the number of beam levels in that row), if applicable.

- They must indicate the total actual loading expected in interconnected bays.

- They must display the maximum total load per bay.

- They must indicate which storage levels allow multiple stacking of unit loads.

Load plaques are typically provided by the rack manufacturer and affixed during installation. Because some systems have different configurations within the same aisle, the safest practice is to place a plaque on every aisle, for every configuration. The majority of rack manufacturers also include their logo, contact information, date of manufacture or installation, and other project-specific identifying or safety details (as shown in the sample image above) on their load plaques; this information is not required by ANSI MH16.1.

If the rack system is reconfigured, modified, or altered, the corresponding load plaque’s information will no longer be valid. Therefore, if any changes are made to the system’s configuration, the rack owner should work with the original rack manufacturer or a qualified rack design engineer to re-evaluate the capacity of the system, develop new load plaques, and affix them to the system.

Want to learn more about load capacity plaques? Download ANSI MH16.1: Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks.