The Pros And Cons Of Labeling Load Capacities On Rack ...

Marking the maximum weight capacity on a pair of beams in a given pallet rack structure can be beneficial to an operation. After all, there are probably multiple labels and tags already adorning the faces of the beams to indicate ...

Why Storage Rack Load Capacity Plaques Are Important To The ...

When you install pallet racking in your facility, every inch of it comes designed specifically to meet local building codes for your configurations and loads. From the height of the materials to the spacing between pallets, the seismic rating, and ...

Load Plaques: Why Your Rack Installation Needs Them

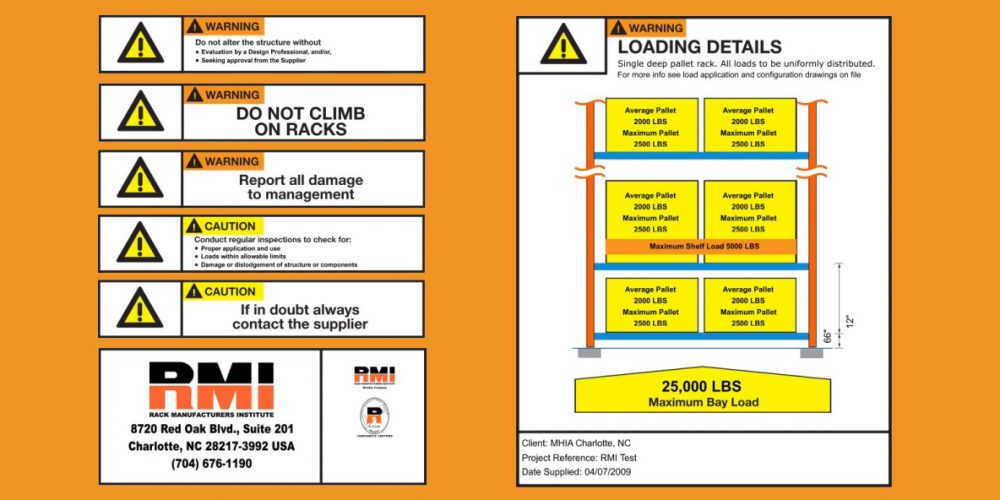

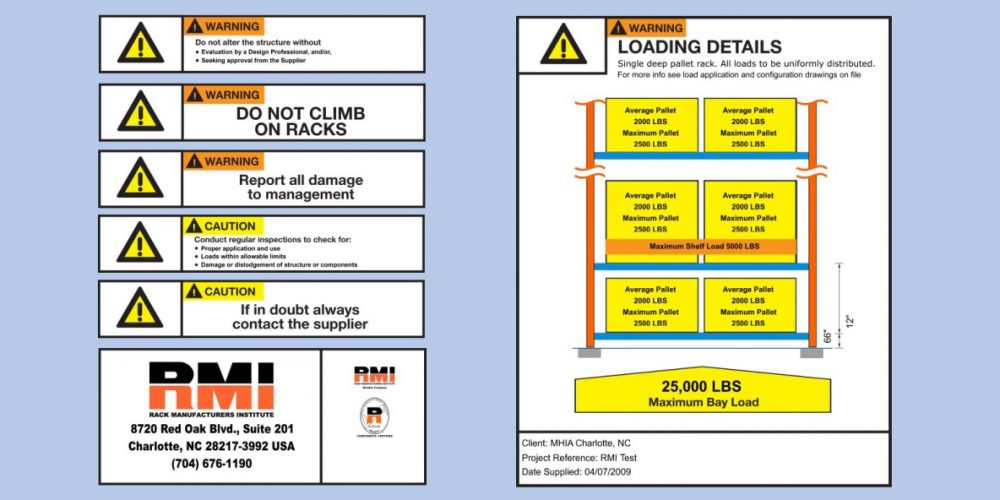

When industrial steel storage rack installations have stamped and sealed engineering documents or load application and rack configuration (LARC) drawings, they should be kept on-site within the facility. These documents include critical details about the maximum safe capacity of the ...

Use Rack Load Capacity Plaques And LARC Drawings For A ...

To ensure a safer, and, therefore, more productive operation, owners of industrial steel storage racking are responsible for posting rack load capacity plaques in conspicuous locations, and should refer to the system manufacturer’s load application and rack configuration (LARC) drawings ...

Why Pallet Quality Is Key To Safe Rack Utilization

Although industrial storage rack systems are specifically designed and engineered to support a given type of pallet and load, simply placing the approved pallet into a storage position isn’t enough to ensure the safety of the structure and facility personnel. ...

The Importance Of Matching Pallets To Rack Type For Safe ...

Products arrive in warehouses and distribution centers on any number of pallet types these days: two-way entry, four-way entry, skids, slip-sheets, nine-block, and more. Some pallets are designed with multiple boards—or stringers—spanning the bottom surface; others have a foot in ...

Why Are Load Capacity Plaques Important?

Regardless of when a steel storage rack installation was designed, commissioned and installed, the original stamped and sealed engineering documentation detailing the maximum safe rack capacity should be kept on-site within a facility. However, chances are that paperwork is likely ...