Why Are Load Capacity Plaques Important?

Regardless of when a steel storage rack installation was designed, commissioned and installed, the original stamped and sealed engineering documentation detailing the maximum safe rack capacity should be kept on-site within a facility. However, chances are that paperwork is likely kept in a filing cabinet, and not easily accessible to the users charged with operating and maintaining the system. Without easy access to the original design information, operators frequently make changes to the system configuration or utilize pallets that exceed the system capacity. Unknowingly, this creates a potentially unsafe operation and work environment.

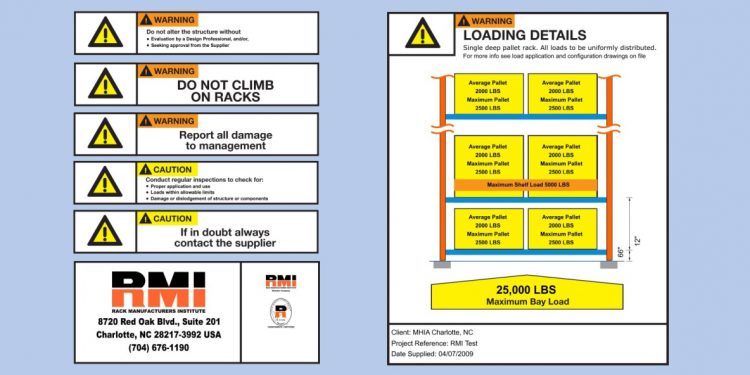

For that reason, RMI’s ANSI MH16.1-2012: Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks, section 1.4.2 states that the rack “owner is responsible for displaying in one or more conspicuous locations a permanent plaque(s)” with the following details:

- The maximum permissible unit load (the combined weight of product and its storage container or pallet) and/or maximum uniformly distributed load per level.

- The average unit load (calculated as the maximum total weight of product expected on all beam levels in any row, divided by the number of beam levels in that row), if applicable.

- The maximum total load per bay.

- Indication of storage levels that support stacking of multiple unit loads.

Typically, the rack manufacturer provides the load capacity plaques for an installation, and a good practice is to place a plaque on every aisle, for every configuration—as there might be different rack configurations within the same aisle. Although not required by the RMI/ANSI MH16.1-2012: Specification, most rack manufacturers also include their logo, contact information, date of manufacture or installation, and other project-specific identifying or safety details (as shown in the example image).

Should the rack be modified or altered in any way, the information included on a load capacity plaque is rendered void. When changing any aspects of their system, it is incumbent on the owner to work with the original rack manufacturer or a qualified rack design engineer to re-evaluate the capacity of the system, develop new load plaques and place them on the system.

Want to learn more about load capacity plaques? Download the RMI/ANSI MH16.1-2012: Specification.