Why Storage Rack Load Capacity Plaques Are Important To The Safe Use Of Racking Systems

When you install pallet racking in your facility, every inch of it comes designed specifically to meet local building codes for your configurations and loads. From the height of the materials to the spacing between pallets, the seismic rating, and everything in between, each storage rack system is unique. And while it may appear that the assembled rack is ready for use post-assembly, there’s one final piece needed to ensure everything is complete: posting the storage rack load capacity plaques.

Requirements for the Use of Storage Rack Load Capacity Plaques

Requirements for the Use of Storage Rack Load Capacity Plaques

The use of and information included on load capacity plaques are governed by RMI’s American National Standard ANSI MH16.1: Design, Testing and Utilization of Industrial Steel Storage Racks, section 4.5. Additionally, ANSI MH16.1 is referenced by the International Code Council’s (ICC) International Building Code (IBC) as the standard for safe design and installation of pallet racks. Therefore, storage rack load capacity plaques are also typically part of state, county, and local jurisdictions’ building codes. Likewise, the Occupational Safety and Health Administration (OSHA) relies on RMI and ANSI MH16.1 for the design, testing, and utilization of pallet rack. This includes the use of load capacity plaques.

Information That Must Be Included

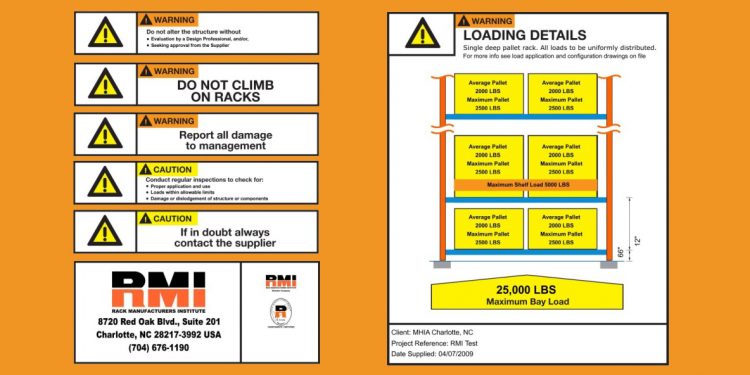

Storage rack load capacity plaques serve as concise, visual documentation of the maximum pallet load capacity each storage position in the racking can hold. Posted on the structure or nearby the system, plaques should be located where employees and operators can see them. They should measure at least 50 square inches for maximum visibility. Information required includes:

- The maximum permissible unit load (the combined weight of product and its storage container or pallet) and/or maximum load per level.

- The average unit load, if applicable. The calculation is the maximum total weight of product expected on all beam levels in any row, divided by the number of beam levels in that row.

- Details about the total actual loading expected in interconnected bays.

- The maximum total load per bay.

- The number and spacing of storage elevations (levels) in the original system design.

When the load capacity plaques are on display, they serve as a guide for operations on how much load the rack system can safely hold. For instance, each pallet rack beam can hold a certain number of pallets — usually two. If each of those pallets weighs 2,000 pounds, the rack beam level can safely support 4,000 pounds. Storage rack load capacity plaques illustrate the weights and loading configurations specific to each rack.

Changes Require Updated Plaques

Another factor to consider is that over time, the needs of a warehouse change. Therefore, facility operators may need to alter beam locations to accommodate different loads. It is very important that when making these changes, the facility operator works with a qualified rack design professional. This is to ensure that the revised beam elevation configuration will still meet RMI and building code requirements. Even seemingly simple changes (such as removing a beam level), can drastically change the load capacity of the system. Add any approved changes to the system to updated load capacity plaques.

Ultimately, the load capacity plaques serve three critical functions:

- Permanent posting of the unit load capacity of the system that operations personnel can reference.

- Visual documentation of the original approved beam and elevation configuration design.

- Identification of the original supplier of the system for consultation prior to making configuration changes.

Get Load Capacity Plaques from the Manufacturer

Sometimes the rack manufacturer provides storage rack load capacity plaques upon installation and commissioning of the system. However, this is not a requirement of ANSI MH16.1. It is the rack owner’s responsibility to make or purchase plaques, either from the manufacturer or another source. Best practice is to display a plaque at every point of system entry and/or every different rack configuration.

Although not required by the ANSI MH16.1, many load capacity plaques frequently contain additional information. This includes details about the manufacturer, the date of system manufacture or installation, safety warnings, and other structure-specific details. If the structure’s configuration changes and load capacities change, update, and mount new load plaques accordingly.

Want more information about load capacity plaques? Purchase RMI’s ANSI MH16.1: Design, Testing and Utilization of Industrial Steel Storage Racks.