The Top Five Things to Know About Rack Fire Protection- Learn the ins and outs of fire protection within your racking systems.

Fire protection plays into every aspect of your operations, and your racking systems are no exception. Here are the top five factors to keep your racking as resistant as possible to fire and smoke damage:

- Know what commodities you store—Fire protection requirements vary depending on what you store. By far the most volatile material to store in your racking is plastic, because when on fire, plastic will burn twice as hot. This increases the requirements for fire protection, which can be an added cost you might want to avoid. Barring the ability to store items not made of plastic, you do have choices in how you store them. While plastic totes have become a popular choice in the last few years due to their durability, longevity, and sustainability, they increase the amount of plastic within your racks. If this is a concern, you can consider going back to cardboard or wood storage containers as an alternative.

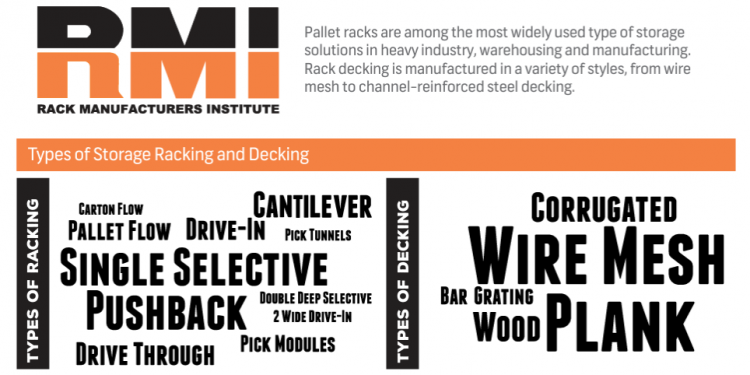

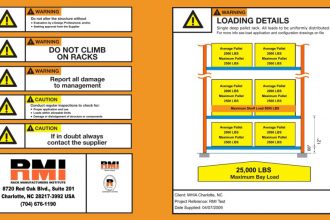

- Know how you plan to store items in your facility—If it will be in racks, understand what type of racks you have in your facility. Pushback, single-back, single row? The issue is that the load within your racks defines your shelves, not the shelving material. If you are stacking pallets back-to-back, the standards may consider that solid shelving. In that case, you might need to install sprinklers within your racks. Understand what your configurations mean in that regard and act accordingly

- Understand your aisle width—The wider your aisles, the less likely a fire might jump across aisles from one rack to another. According to fire protection standards, it’s safer to use eight-foot aisles versus four, and will require less water availability via sprinklers.

- Understand the height of your racks—Similar to aisle widths, the height of your racking will change the fire protection requirements within your facility. Once a rack extends over 25 feet in height, you will need to add flues. The taller the building, the more water accessibility required, as well.

- Know the types of sprinklers are best for your operations—There are several types of sprinkler systems to choose from in your distribution center, so understanding the best fit for your operations is important. In-rack sprinkler systems are common and can quickly extinguish a fire on a specific rack, containing a fire to the spot. Also common are wet pipe sprinklers, which have stored water and activate by detecting heat. For facilities in colder climates susceptible to freezing, there are dry pipe systems that don’t store water, but compressed air. Upon detection of a fire, these sprinklers release water into a pipe that leads to sprinkler heads. There are also early suppression, fast response (ESFR) sprinklers to consider, which will provide wider protection than in-rack fire systems.

No matter what type of sprinkler system you need and use, it’s important to regularly revisit and assess your protection, especially as your DC environment changes or grows.