Rack Codes & StandardsRack Design & InstallationRack Inspection & MaintenanceRack Repair & ReconfigurationUncategorized

A Look at ANSI MH32.1

In order to safeguard your employees on elevated work surfaces, you’ll need to follow these standards. In the warehouse, much of your employee’s work will take place in overhead work areas that are designed to maximize the vertical space you ...

Pairing Pallets and Racking

Before making any rack purchase, it’s important to understand the type and condition of your pallets. You’ve got a big investment in your racking system, so you want to get it right. One of the biggest considerations when choosing your ...

Automated Guided Vehicles (AGVs) and Your Aisles

A great productivity enhancer, make sure your facility is prepared for the addition of AGVs. Once you’ve made the decision to add AGVs to your facility and after finding the right partner, identifying the pain points the equipment will solve, ...

Nine Benefits Of Rack Repair Kits

Pallet rack damage happens, often due to an impact from a forklift as it transports a load through the facility. Upon identification of a damaged rack section the structure should be isolated, and a qualified, professional rack engineer should be ...

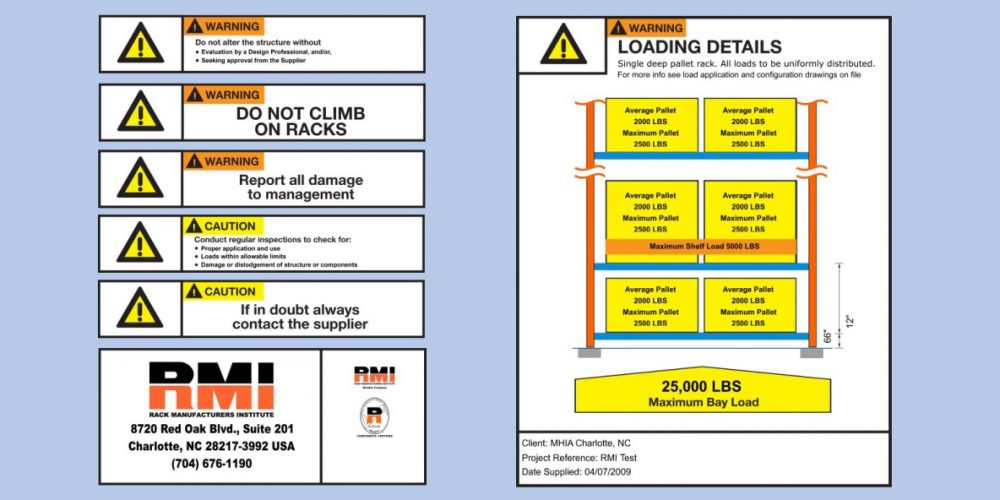

Load Plaques: Why Your Rack Installation Needs Them

When industrial steel storage rack installations have stamped and sealed engineering documents or load application and rack configuration (LARC) drawings, they should be kept on-site within the facility. These documents include critical details about the maximum safe capacity of the ...

How Picker Ergonomics Is Improved By Utilizing Pallet Separators In ...

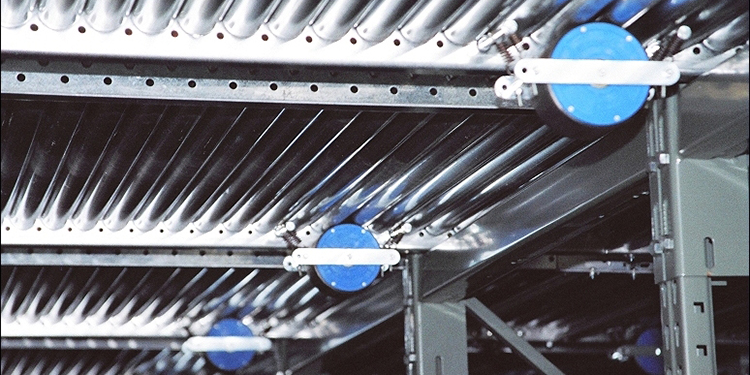

Engineered to hold multiple pallet loads in individual lanes pitched downward, high-density pallet flow (or “gravity flow”) rack is frequently used in case-picking operations. In these systems, full pallets of product are loaded from the back (or “charging”) end and ...

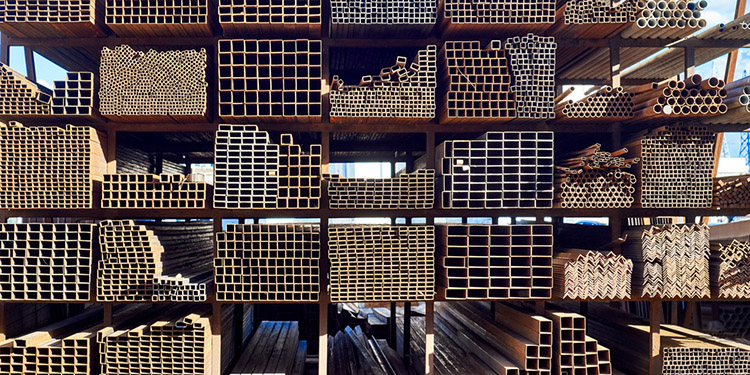

Using Storage Rack Outside? Follow These Design And Use Best ...

Not every industrial steel storage rack installation is inside the four walls of a warehouse, distribution center or big box store. Instead, some racks are erected outside a building to store goods outside, frequently because of convenience or necessity. Like ...

Safeguard Rack Columns Against Forklift Impacts With These Five Protective ...

To help protect rack columns from forklift and other vehicle impacts, there are a number of optional rack guard accessories that can be added to aisle-side or end-facing rack columns (or to the floor in front of them). Additionally, for ...

The “Dos And Don’ts” Of Pushback Rack

Engineered to store pallet loads on both sides of an aisle, industrial pushback racking storage systems deliver cubic densities that are approximately 25% to 65% greater than selective racking. The systems are built with a series of nested carts that ...

Jammed Pallet Flow System? Follow These Best Practices To Safely ...

Pallet hang-ups can happen in even the best maintained, properly loaded pallet flow rack system (also known as “gravity flow”). Jams can be caused by a variety of reasons, including a pallet that’s settled onto the tracks, debris in the ...