How Picker Ergonomics Is Improved By Utilizing Pallet Separators In Flow Rack

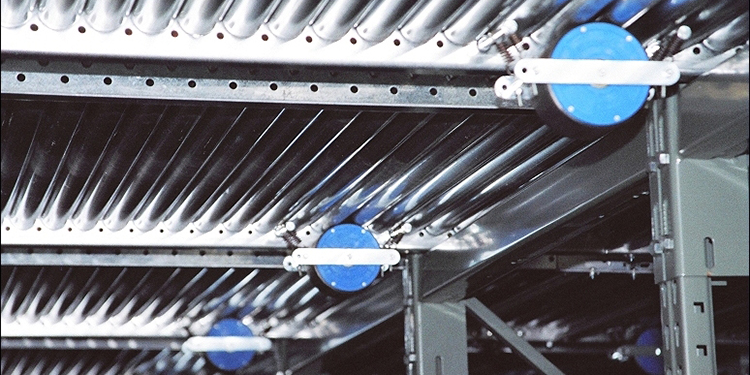

Engineered to hold multiple pallet loads in individual lanes pitched downward, high-density pallet flow (or “gravity flow”) rack is frequently used in case-picking operations. In these systems, full pallets of product are loaded from the back (or “charging”) end and placed atop a series of rollers or skate wheels. Gravity draws the pallets forward down the slope to the pick-face, or discharging, end. Associates stationed at the discharging end pick split cases from the full pallets. When a pallet of products is depleted, the empty pallet is removed and the subsequent loads in the lane advance forward.

Because the pallets in the lane rest against each other, however, a substantial amount of force is placed on the pallet at the pick-face. Known as pallet flow back pressure, this equates to approximately 6% of the full weight of all rear pallets.

3-deep system, 2,500 lb. load. Back pressure = .06 x 2,500 lbs. x 2 pallets = 300 lbs.

That increased force can make it extremely difficult for a picker to lift and remove the front pallet when empty. A worker who tries to do so is at an increased risk of sustaining an ergonomic injury due to repetitive bending, stretching and straining.

To negate pallet flow back pressure, an interlocking pallet separator (sometimes referred to as a “hold-back” or “braking” device), can be added to the lanes. This component pops up above the roller or skate wheel tracks to stop and hold the series of pallets behind the one at the pick-face, typically at a distance of 6 to 12 inches. With a pallet separator, the forces that prohibit the front pallet from being removed easily are mitigated. Once the empty pallet has been removed, the associate releases a manual latch to advance the pallet flow and allow the next pallet to slide into the pick-face position.

Additionally, pallet separators can be used in deep-lane flow to relieve the pressure otherwise experienced by the lift truck. Because it likewise eliminates the forces that prevent easy removal of the empty pallet, forklift driver productivity increases, and product damage is prevented.

For even greater control of pallet movement as each shifts forward in a pallet flow lane, two other accessories can be utilized:

- Speed Controllers: Ensuring that pallets advance at a controlled, steady pace, these braking devices are mounted below the roller tracks or dropped in on top of the wheeled tracks, typically at a single pallet interval. The controllers not only minimize the risk of product or pallet damage, but they also help to keep the loads centered in the lane, reducing the risk of a hang-up.

- Ramp Stops: Also referred to as “end stops,” these devices are bolted onto the discharge end of the pallet flow rack lane. They slow the advance of the first pallet, stopping it safely and holding it securely at the pick-face.

Want more guidelines for the safe use of storage racks? Purchase RMI’s publications “Considerations for the Planning and Use of Industrial Steel Storage Racks” and “Guideline for the Assessment and Repair or Replacement of Damaged Rack.”