How Picker Ergonomics Is Improved By Utilizing Pallet Separators In ...

Engineered to hold multiple pallet loads in individual lanes pitched downward, high-density pallet flow (or “gravity flow”) rack is frequently used in case-picking operations. In these systems, full pallets of product are loaded from the back (or “charging”) end and ...

Safeguard Rack Columns Against Forklift Impacts With These Five Protective ...

To help protect rack columns from forklift and other vehicle impacts, there are a number of optional rack guard accessories that can be added to aisle-side or end-facing rack columns (or to the floor in front of them). Additionally, for ...

The “Dos And Don’ts” Of Pushback Rack

Engineered to store pallet loads on both sides of an aisle, industrial pushback racking storage systems deliver cubic densities that are approximately 25% to 65% greater than selective racking. The systems are built with a series of nested carts that ...

Jammed Pallet Flow System? Follow These Best Practices To Safely ...

Pallet hang-ups can happen in even the best maintained, properly loaded pallet flow rack system (also known as “gravity flow”). Jams can be caused by a variety of reasons, including a pallet that’s settled onto the tracks, debris in the ...

How Pallets Contribute To The Safe Use Of Pushback Rack ...

As with the vast majority of industrial steel storage rack systems, last-in/first-out (LIFO) pushback racking systems are designed for use with specific pallet types, loads and rack configurations. Operators, therefore, should be trained to only load a pushback system with ...

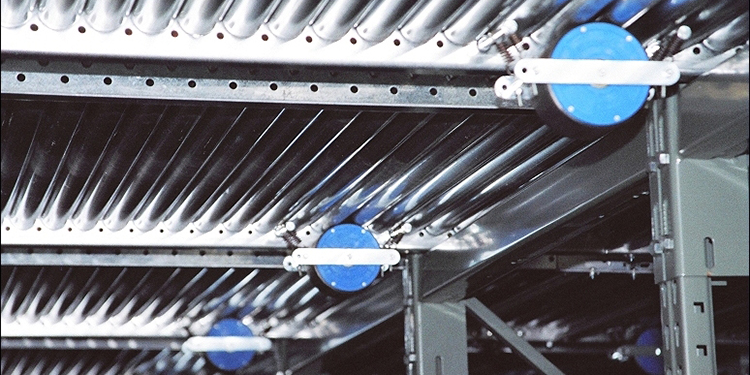

The “Dos and Don’ts” Of Pallet Flow Rack

Whether you own a pallet flow rack system (also referred to as “gravity flow” rack), or are considering investing in one, ownership comes with a variety of responsibilities. These include ensuring that the structure complies with applicable standards and is ...

Why Are Pallets Important For Pushback System Safety?

Last-in/first-out (LIFO) pushback racking systems (like the vast majority of industrial steel storage rack systems) are designed for use with specific pallet types, loads and rack configurations. For that reason, it is critically important to ensure that operators only load ...

Recommended Safety Practices For Case Picking Of Products Stored In ...

Because they support high-throughput order fulfillment of single product—typically fast movers—some operations utilize pushback racking storage systems as part of their picking process. In order to ensure that pickers are able to perform their assigned tasks safely when working with ...

The Safest Way To Unjam A Pushback Rack System

Even though the wheeled carts in industrial pushback racking storage systems are designed to travel smoothly backward and forward from the point of pallet insertion and removal, jams can sometimes occur. Common causes of hang-ups include improper loading of pallets, ...

Best Practices In Safe Operation Of Pushback Rack

Industrial pushback racking storage systems are engineered to store pallet loads on both sides of an aisle at higher cubic densities approximately 25% to 65% greater than selective racking. That’s because these systems are built with a series of nested ...