Why Pallet Rack LARC Drawings Are Important

Although industrial steel storage rack is designed and engineered with adjustable beams to accommodate different load heights, for safety never change the configuration without consulting the pallet rack LARC drawings and a qualified design professional first. LARC is an abbreviation ...

Supplemental Calculations For Pallet Rack Design Engineers Illustrate Use Of ...

When the newest version of the American National Standard for pallet rack—ANSI MH16.1-2021: Design, Testing, and Utilization of Industrial Steel Storage Racks—was released by the Rack Manufacturers Institute (RMI), it included significant revisions to the calculation methodologies used by engineers ...

How Rotationally Rigid Connections Enhance Rack Stability In Seismic Events

Depending on where a warehouse or distribution center (DC) is located within the United States, the design and engineering of its industrial steel storage rack structures may be subject to seismic requirements. As outlined in RMI’s ANSI MH16.1: Specification for ...

Load Plaques: Why Your Rack Installation Needs Them

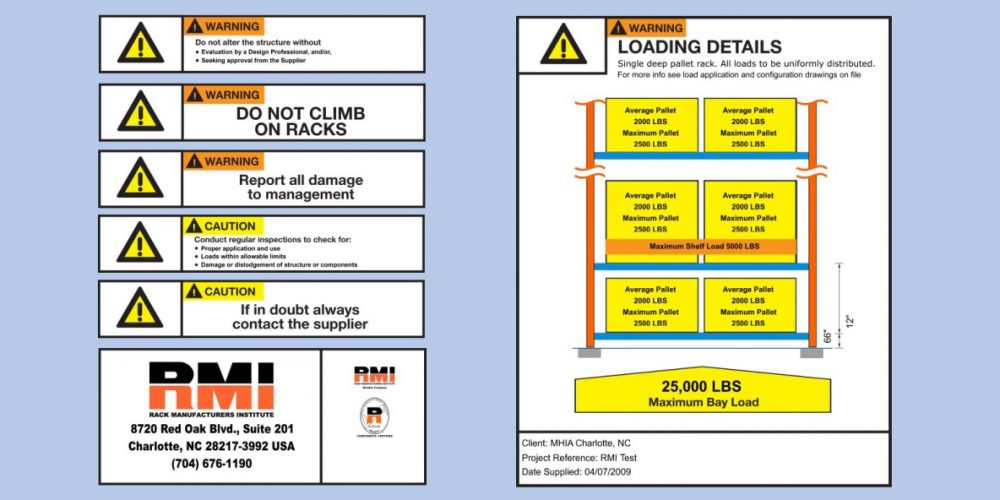

When industrial steel storage rack installations have stamped and sealed engineering documents or load application and rack configuration (LARC) drawings, they should be kept on-site within the facility. These documents include critical details about the maximum safe capacity of the ...

The “Dos and Don’ts” of Reconfiguring Pallet Rack

Most pallet rack is manufactured for adjustability and assembly in multiple configurations, which might lead a system owner or user to assume a current installation can be reconfigured safely to increase storage density. While making such changes to racking, such ...

How Height-To-Depth Ratio Contributes To Overall Storage Rack Stability

A key objective of safe rack design is to ensure the finished structure won’t topple over when subjected to horizontal forces such as an earthquake, forklift impact, or high wind. To significantly minimize this risk, Section 8.1 of RMI’s ANSI ...

Minimize The Risk Of Load Beam Disengagement With Locking Devices

To reduce the chance of a load beam becoming disengaged from the storage rack structure, rack manufacturers typically include locking clips, pins and/or bolts. They secure the connection of the beams to the upright columns at every point of contact ...

Rack Safety, Design Pivotal In Growth Of MHI’s Oldest Industry ...

This article by Stephen Murdock originally appeared in the fourth quarter 2020 issue of MHI Solutions magazine and has been reprinted in its entirety with permission. The Rack Manufacturers Institute (RMI), officially the oldest Industry Group in MHI, has seen ...

Why You Shouldn’t Mix Rack Components From Different Manufacturers In ...

While rack columns and beams constructed by different manufacturers may appear similar, mixing components in the same structure — also sometimes called “intermembering” — is unsafe and not recommended. That’s because connecting incompatible rack components, which can erroneously occur as ...

How Point Loads And Uniformly Distributed Loads Affect Safe Rack ...

When placed in industrial steel storage racks, a uniformly distributed load is one whose weight is evenly spread over the entire surface of the rack’s beams or deck. Conversely, a point load is one with its weight significantly concentrated in ...