How Semi-Automated Pallet Handling Systems Increase Storage Density, Throughput

Nearly every company that stores inventory struggled with supply chain disruptions during the pandemic. Many experienced out-of-stocks and backorders that lasted for months, resulting in unhappy customers. In response, warehouses and distribution centers that previously only held on to a ...

Over-The-Dock Racking: Special Considerations For Busy Loading Zones

When it comes to optimizing space in a warehouse, distribution center, or production facility, safety should always be the top priority. One often overlooked area that can provide a cost-effective solution for the need for additional storage is above the ...

People And Pallet Rack: Safety And Signage Best Practices

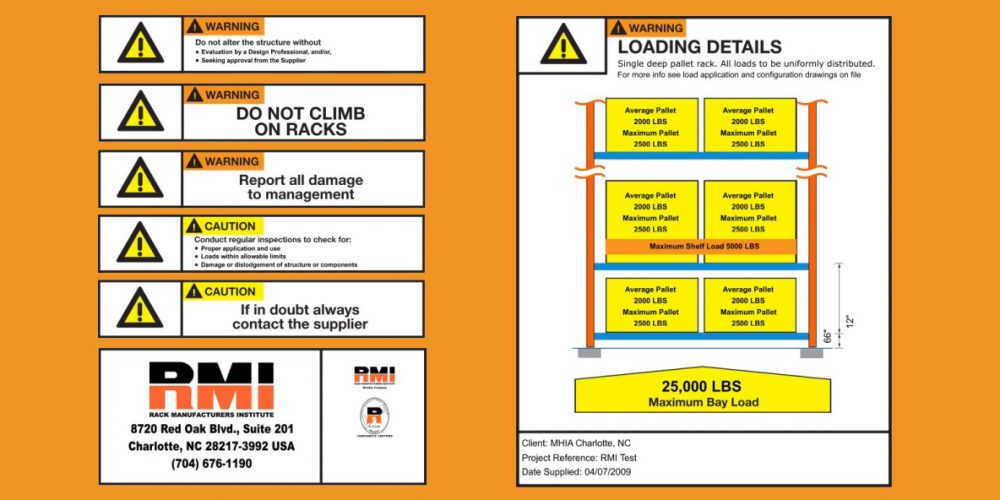

With more than 9.1 billion square feet of warehousing space in the U.S., pallet rack is everywhere. That pervasiveness, however, means that personnel could easily take its safety and reliability for granted. Therefore, owners and operators of warehouses and distribution ...

Relocating Pallet Rack To A New Facility? Read This First, ...

The previous post outlined three key areas a rack owner should consider prior to moving a storage rack system from one building to another. These include building codes, seismic activity, and fire suppression. There are, however, several other considerations to ...

Relocating Pallet Rack To A New Facility? Read This First, ...

Because storage racks are comprised of beams and uprights that can be reconfigured — and because each system represents a significant investment — free-standing pallet racks appear easy to relocate. That is, if an operation is moving from one address ...

Learn How Converting Static Pallet Rack To Carton Flow Improves ...

With projections estimating that the North American e-commerce market will multiply at a compound annual growth rate (CAGR) of 12.5% between now and 2027, it is increasingly likely that facilities configured to primarily handle pallets will need to shift to ...

The Pros And Cons Of Labeling Load Capacities On Rack ...

Marking the maximum weight capacity on a pair of beams in a given pallet rack structure can be beneficial to an operation. After all, there are probably multiple labels and tags already adorning the faces of the beams to indicate ...

How Does R-Mark Certification Benefit Storage Rack And Decking Buyers?

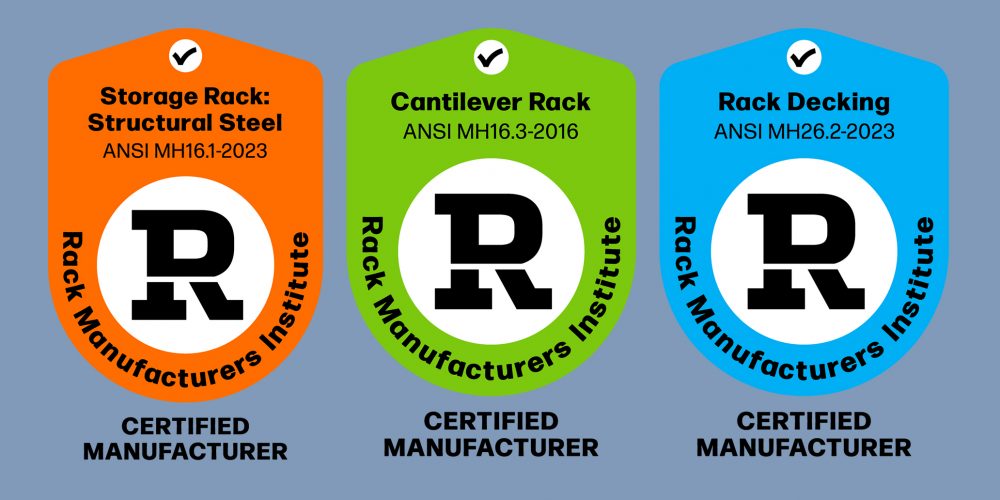

The Rack Manufacturers Institute (RMI) recently revised and expanded its R-Mark® Certification program. Originally created in 1999, the voluntary program is for manufacturers of industrial steel storage racks and of rack decking. With the new revisions, R-Mark certification now applies ...

Rack Manufacturers Institute Updates R-Mark Certification Program

Established more than two decades ago, the Rack Manufacturers Institute’s (RMI) R-Mark® Certification program has been recently revised and expanded. While it remains a voluntary program for manufacturers of industrial steel storage racks and of storage rack decking, R-Mark certification ...

Why Storage Rack Load Capacity Plaques Are Important To The ...

When you install pallet racking in your facility, every inch of it comes designed specifically to meet local building codes for your configurations and loads. From the height of the materials to the spacing between pallets, the seismic rating, and ...