Keep Workers At Floor Level Safe From Falling Objects With ...

Installed on elevated work platforms, pick module walkways, and rack supported platforms, kickplates (also called toe boards or toe guards) protect associates working at floor level from objects that may slide or fall off the structure overhead. These vertical plates ...

How Elevated Work Platform Guardrails Enhance Worker Safety

With warehouse and distribution center storage at a premium, many operations are looking up and maximizing the overhead space in their facilities to expand their picking and fulfillment capacity. By utilizing elevated work platforms, pick modules, or rack supported platforms, ...

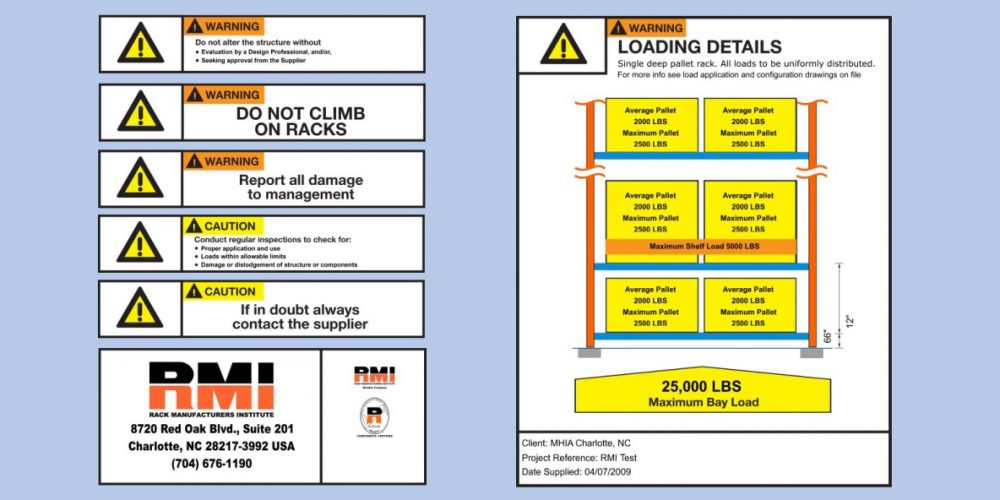

Load Plaques: Why Your Rack Installation Needs Them

When industrial steel storage rack installations have stamped and sealed engineering documents or load application and rack configuration (LARC) drawings, they should be kept on-site within the facility. These documents include critical details about the maximum safe capacity of the ...

The “Dos and Don’ts” of Reconfiguring Pallet Rack

Most pallet rack is manufactured for adjustability and assembly in multiple configurations, which might lead a system owner or user to assume a current installation can be reconfigured safely to increase storage density. While making such changes to racking, such ...

Safeguard Rack Columns Against Forklift Impacts With These Five Protective ...

To help protect rack columns from forklift and other vehicle impacts, there are a number of optional rack guard accessories that can be added to aisle-side or end-facing rack columns (or to the floor in front of them). Additionally, for ...

The Importance Of Horizontal Clearance In Seismic Storage Rack Installations

Everything moves when an earthquake occurs. That includes the ground, the walls and support columns within a warehouse or distribution center, and the storage rack systems installed inside those structures. To minimize the risk of injury to any persons working ...

How Height-To-Depth Ratio Contributes To Overall Storage Rack Stability

A key objective of safe rack design is to ensure the finished structure won’t topple over when subjected to horizontal forces such as an earthquake, forklift impact, or high wind. To significantly minimize this risk, Section 8.1 of RMI’s ANSI ...

The “Dos and Don’ts” Of Pallet Flow Rack

Whether you own a pallet flow rack system (also referred to as “gravity flow” rack), or are considering investing in one, ownership comes with a variety of responsibilities. These include ensuring that the structure complies with applicable standards and is ...

Minimize The Risk Of Load Beam Disengagement With Locking Devices

To reduce the chance of a load beam becoming disengaged from the storage rack structure, rack manufacturers typically include locking clips, pins and/or bolts. They secure the connection of the beams to the upright columns at every point of contact ...

Don’t Miss RMI’s Two ProMatDX 2021 Education Seminars On Rack ...

At ProMatDX 2021, members of the Rack Manufacturers Institute (RMI) will present two separate education sessions covering the safe design and use of industrial steel storage rack. Open to all ProMatDX attendees free of charge, the two sessions will include ...