The Difference Between Racking and Shelving

Picking the right racking or shelving solutions for your specific operations can be a lengthy process and one that should be carried out with a credentialed racking or shelving manufacturing partner.

Having a good understanding of what systems and options are available is a smart starting place. While both products, by definition, are material handling structures with similar purposes, racking and shelving differ in characteristics. One An important concept to understand when choosing between racking and shelving is knowing the difference between these two storage solution types.

Both types of storage fall under the category of material handling structures or systems made from approved steels, consisting principally of vertical upright frames and horizontal beams or shelves used to support product, either for in-plant use or as inventory. That’s the definition, but to differentiate, you need to drill down into their characteristics.

Beginning with racking, there are several racking types: selective or pallet, push-back, pallet- and carton-flow racks, drive-in and drive-through, cantilever, pick modules, rack-supported platforms, rack-supported buildings, shuttle racks, automated storage and retrieval systems (ASRS). The racking system can be either free-standing within an existing warehouse or industrial/commercial facility or be a rack-supported system where the racking supports the exterior framework and cladding of the building. Most operations will load racking with a machine such as a forklift, crane, or shuttle cart. Even in the case of hand-load racking involve a man-aboard lift or crane.

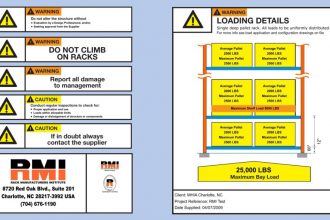

The typical loads that go into racks are palletized products that can weigh 1,000 pounds or more—but this is not a hard and fast rule. Selective racking and similar racks fall under the ANSI MH16.1 standard, while cantilever racking falls under the ANSI MH 16.3 standard. To better understand the varieties and differences, visiting the RMI website at www.MHIa.org/RMI or reaching out to an RMI member organization for explanations, brochures and other educational materials is a good place to start.

Shelving, by contrast, is available in two basic models: boltless and bin. Shelving is typically free-standing but can be used for both pick modules and shelving-supported platforms. Boltless shelving is more akin to racking with vertical upright frames and shelf beams; however, the shelf beams typically require a decking surface for hand-loading with each shelf load usually weighing less than 1,000 pounds.

Bin shelving features uprights, but these tend to run from only12 inches to 24 inches deep, along with solid sheet-metal decks that range from 12 inches to 60 inches in width. Again, the shelves are typically hand-loaded with loads weighing around 50 pounds per square foot or less.

Boltless shelving and bin shelving each have their own distinct ANSI design standards. Boltless is covered under ANSI MH28.2 and bin shelving is covered under the ANSI MH28.1 standard. Under the Material Handling Industry (MHI) umbrella, you’ll find shelving covered by the Storage Equipment Manufacturers Association (SMA), www.MHIA.org/SMA.