How Picker Ergonomics Is Improved By Utilizing Pallet Separators In ...

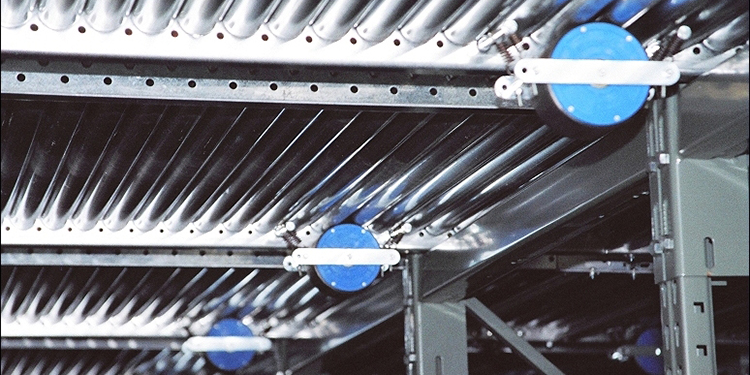

Engineered to hold multiple pallet loads in individual lanes pitched downward, high-density pallet flow (or “gravity flow”) rack is frequently used in case-picking operations. In these systems, full pallets of product are loaded from the back (or “charging”) end and ...

How Height-To-Depth Ratio Contributes To Overall Storage Rack Stability

A key objective of safe rack design is to ensure the finished structure won’t topple over when subjected to horizontal forces such as an earthquake, forklift impact, or high wind. To significantly minimize this risk, Section 8.1 of RMI’s ANSI ...

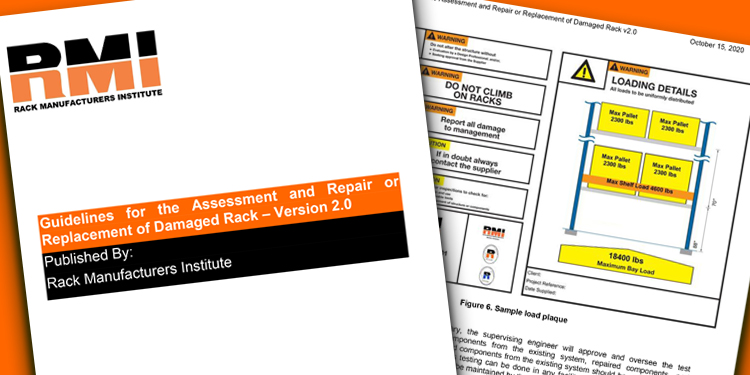

Updated Rack Repair Guidelines Released by RMI

The Rack Manufacturers Institute (RMI) has updated its existing publication, Guidelines for the Assessment and Repair or Replacement of Damaged Rack, with the latest information as a reference for owners and users of industrial pallet rack systems. The latest release, ...

How Point Loads And Uniformly Distributed Loads Affect Safe Rack ...

When placed in industrial steel storage racks, a uniformly distributed load is one whose weight is evenly spread over the entire surface of the rack’s beams or deck. Conversely, a point load is one with its weight significantly concentrated in ...

Why Rack Systems Must Comply With Building Codes

Industrial steel storage rack owners are sometimes surprised to learn that the verification of the structure’s safety and design is governed by one or more local jurisdictions, such as state, county or local municipality. Additionally, this permitting and inspection process ...

Why Pallet Flow Systems Are Designed For Specific Pallets And ...

The vast majority of industrial steel storage rack systems—including pallet flow (or “gravity flow”) rack—are engineered specifically for a single storage purpose. Likewise, when designing a high-density pallet flow system, there are a number of variables that must be taken ...

Applying Pallet Separators, Speed Controllers To Flow Rack

Because high-density pallet flow (also called “gravity flow”) rack is engineered to hold multiple pallet loads in a lane with a downward pitch, they are increasingly popular for use in case-picking operations. Full pallets are loaded from the back, or ...

Point Versus Uniformly Distributed Loads: Understand The Difference

When placing loads of equal weight in storage racks, it’s important to remember that all pallets or loads are not created equal. Some pallets are designed with multiple boards—or stringers—spanning the bottom surface; others have a foot in each corner. ...

What’s Height-To-Depth Ratio, And Why Is It Important?

To significantly minimize the risk of a single row of standard steel storage rack from becoming unstable and overturning due to a seismic event, wind or forklift impact, Section 8.1 of RMI’s ANSI MH16.1-2012: Specification for the Design, Testing and ...

Don’t Forget To Check Permitting Requirements For Your Proposed Rack ...

Whether planning for a new rack system in a new location, or a new rack system in an existing location, the system cannot be installed until all applicable building codes have been satisfied. Further, a building permit must be issued ...