Identifying Your Used Racking

While used racking can be a bargain, it’s essential you understand its origins. If you’ve just moved into a brownfield facility, odds are you are getting more than its four walls—you’ve probably inherited its rack systems, as well. While that ...

The Top Five Things to Know About Rack Fire Protection- ...

Fire protection plays into every aspect of your operations, and your racking systems are no exception. Here are the top five factors to keep your racking as resistant as possible to fire and smoke damage: Know what commodities you store—Fire ...

Planning Your Rack System—Part Two: Drilling down into specific rack ...

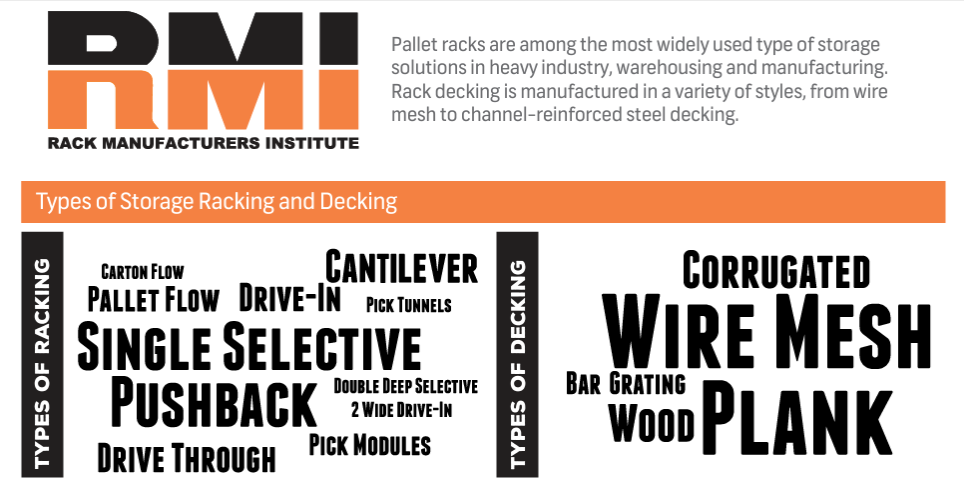

In part one of our post “Planning Your Rack System,” we explained the basic differences in racking materials, density versus selectivity, and more. In this post, we’ll explain more about the various racking configurations and how each might work in ...

Planning Your Rack System- Part 1

With myriad options to choose from, this explainer will help you zero in on the right system for your operations. Every distribution center and manufacturing operation relies on racking. While that’s a given, the various configurations and options of racking ...

Load Capacity Requirements in the new RMI Storage Rack Standard ...

The revised American National Standard for storage rack, ANSI MH16-1-2021, published by the Rack Manufacturers Institute (RMI), includes new requirements for calculating the load capacity for a pallet rack application. The previous standard, published in 2012, calculated capacities using only ...

New Employee Training: The Basics of Loading and Unloading Your ...

When you bring in new hires, essential training includes rack loading/unloading safety. Working in the material handling industry brings with it plenty of safety risks. In fact, in the warehouse, one in 20 employees is injured every year, according to ...

Safely Storing High-Value Items: Your rack installation must hold up, ...

High-value items in the warehouse can take on many different looks and definitions. They could look like slow-moving items that must be ready at a moment’s notice, for instance. Think one of the many FEMA warehouses around the country, where ...

Protecting Your Racking Investment

You’ve just purchased new racking—don’t leave anything to chance. Protect and inspect for a long-lasting product. You’ve gone through the process of selecting the right racks for your operations and installation is scheduled. With a big investment, your next step ...

Adjusting Aisle Width for VNA Trucks

Before closing up your aisle space, have a plan for getting it right. Space is getting tight in your facility, so you’ve opted to add some tighter and higher racking to the mix. Complementing that might be the addition of ...

Adjusting Rack Levels

Initial rack configurations may not work for the long haul. Here’s how to make adjustments. No business stays static over a lifetime, and the same applies to its warehouses. The equipment in a given warehouse may also through changes over ...