Using Storage Rack Outside? Follow These Design And Use Best Practices

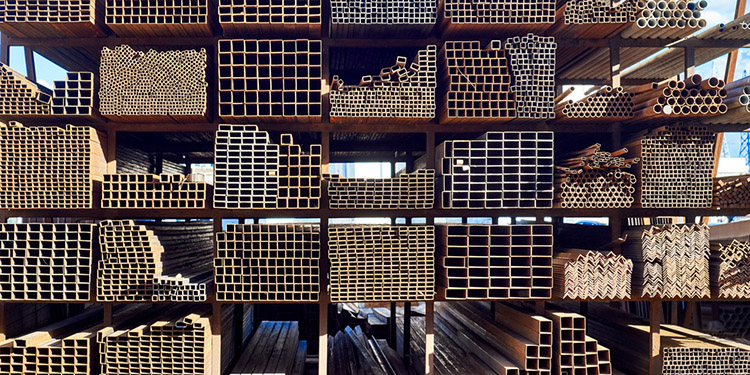

Not every industrial steel storage rack installation is inside the four walls of a warehouse, distribution center or big box store. Instead, some racks are erected outside a building to store goods outside, frequently because of convenience or necessity. Like their indoor counterparts, when they are properly designed, engineered, installed, maintained and routinely inspected, outdoor storage racks offer the same degree of safety and functionality. Storage rack located outside is also subjected to site-specific wind forces and snow loads, in addition to product load and possibly seismic forces. All these factors must be accounted for in the design of the rack.

There are, however, some best practice design and use recommendations that can contribute to extending the maximum useful life of an outdoor racking system. These include:

- Specialized finish. Due to exposure to humidity or extreme weather, the finish on a rack used outside should be formulated for outdoor applications. If the rack manufacturer typically applies a painted finish, verify that the paint to be used is engineered to withstand variable environmental conditions without deteriorating. If not, consider specifying a galvanized finish to ensure that that rack will not rust or corrode over time.

- Slab capacity. Nearly every rack system is designed with the expectation that the rack will anchored into a concrete slab with a rated design capacity. Yet not every outdoor location has a concrete slab; asphalt, gravel, or other surfaces are far more common. In general, installation of rack on surfaces other than concrete is not recommended unless special accommodations are made. Consult your design engineer if there are any questions.

- Water drainage. Depending on the rack system’s design configuration, there may be places within the structure where water can potentially pool. This increases the risk of rust, corrosion, and damage to the rack. Confirm with the rack engineer that the system’s configuration will prevent pooling water.

Post-installation, safety considerations surrounding the use of rack installed outside include:

- Regular inspections. All racks, regardless of their location, should be routinely reviewed and evaluated for damage—including that caused by impacts with products or material handling equipment or by exposure to the elements.

- Common sense. Made of steel and reaching 30-feet high or taller, the potential exists for storage racks to conduct electricity if struck by lightning, or to fall over during extreme winds. For safety, personnel should stay away from outdoor storage racks during thunderstorms or other extreme weather occurrence.

Looking for additional information on the safe use of structural steel storage rack? RMI offers guidance in its publication Considerations for the Planning and Use of Industrial Steel Storage Racks.