How Seismic Design Categories And Site Coefficients Impact Safe Rack Design

Design decisions for racks to be used in facilities with a greater risk of seismic activity are based on a number of factors, including seismic design categories and site coefficients. Information about each is used by a qualified rack engineer will use when designing a rack to reduce the risk of its collapse—and increase the safety of persons in proximity to it—should an earthquake occur.

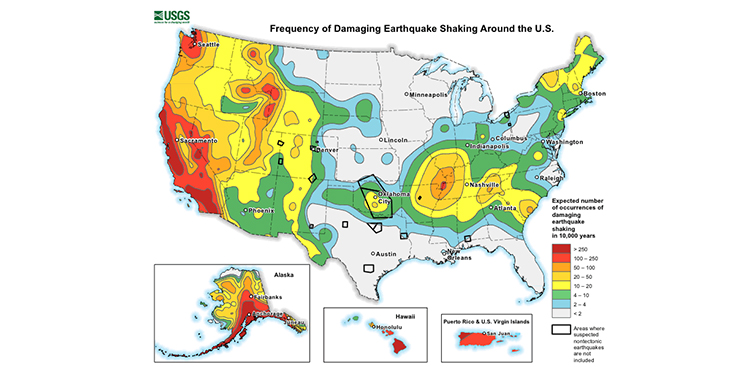

Seismic design categories (SDCs) are classifications assigned to a facility based on the anticipated severity of ground motion during an earthquake in a given location. These categories range from A to F, with A being an area where expected ground shaking is likely to be minor, and F being a major active fault line.

The site coefficient is the local determination of ground composition and its anticipated movement in an earthquake. For example, hard rock will react differently than soft clay. This information informs the SDC of a geographic region.

In terms of rack engineering, the rack manufacturer needs this information prior to designing the rack. This information is typically contained in documentation provided by the building designer. If the SDC or site coefficient of a facility is unknown the rack design will have to use SDC D. That classification signifies the areas expected to experience ground shaking in an earthquake, even if the site is not in close proximity to a major active fault line.

Designing the rack to these requirements ensures that the structure will perform safely in a worst-case scenario. However, doing so can unnecessarily increase the overall cost of the rack if it is actually located in an area with better site characteristics. Racks engineered to meet seismic safety requirements typically have thicker and larger base plates with more anchorage to secure each column to the floor, as well as utilizing much stronger columns, stronger bracing and stiffer beam-column connections. This increase in materials translates to an increase in overall rack cost. Therefore, it’s in the rack owner’s best interest to determine the SDC and site coefficient of their facility location and share those details with the rack design engineer to ensure the safest and most cost-effective rack design.

Section 2.6, “Earthquake Loads,” of the recently updated ANSI MH16.1-2012 (R2019): Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks, published by RMI, includes a complete listing of the calculations to be performed by a qualified rack design engineer. For additional information on seismic design requirements for rack safety, purchase the standard here.