Key Safety Considerations For Outdoor Storage Racking

Sometimes it’s more convenient—or simply necessary—to store certain items or loads outside instead of inside the four walls of a facility. And—when properly designed, engineered, installed and maintained—outdoor industrial steel storage racks offer the same degree of safety and functionality ...

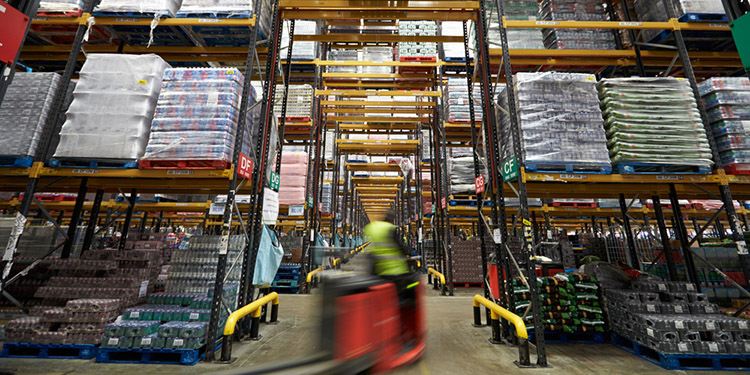

Safe Spacing Matters: Pallet Load Clearance Recommendations For Storage Rack

To minimize the risk of a pallet load and/or handling equipment colliding with a rack column or another load—creating an unsafe situation—storage rack design engineers incorporate a space allowance around the widest part of the load envelope when calculating the ...

Walking On Wire Mesh Rack Decking: Is It Safe?

Is it safe to walk on wire mesh rack decking? In a single word, the answer is “no.” Welded wire rack decking is not engineered for pedestrian use. Because decking often supports loads weighing thousands of pounds, warehouse associates at ...

Pallet Beam Deflection: How Much Is Acceptable?

When the specifications for a pallet support beam are determined by a qualified rack design engineer, the maximum amount of deflection—or bowing—permissible is included in the calculations as noted in Section 5.3 of RMI’s ANSI MH16.1-2012: Specification for the Design, ...

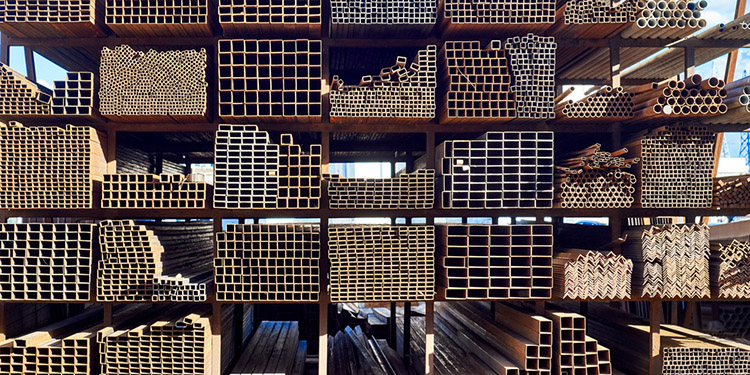

Cantilevered Storage Rack Safety 101

Cantilevered rack structures are comprised primarily of a central, vertical column from which horizontal arms project perpendicularly on one or both sides, with no vertical column connecting the arms on the aisle face. Either free standing or top-tied, these racks ...

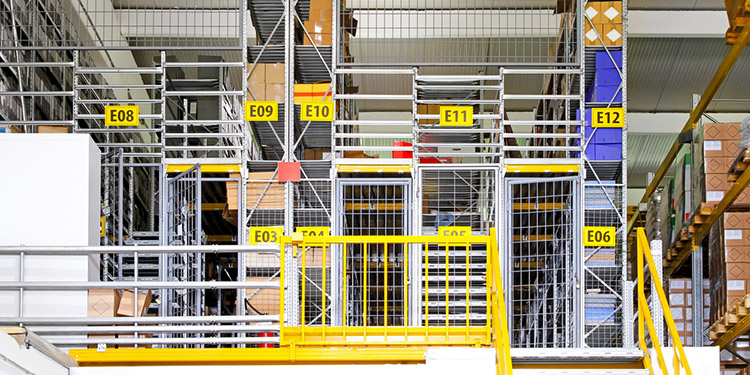

Protecting Workers on Rack Supported Platforms, Pick Modules

To keep workers safe when picking items stored at levels above the facility floor—such as in pick modules or on shelving within rack supported platforms—guidelines are offered in RMI’s ANSI MH16.1-2012: Specification for the Design, Testing and Utilization of Industrial ...

Why Horizontal Clearance Is Important In Seismic Rack Installations

When an earthquake happens, the ground moves. And, shortly thereafter, any vertical structures on top of the shaking ground move too. That includes both the walls and support columns of a warehouse, and the storage rack inside those structures. In ...

RMI’s New Video Offers Introduction To System Selection

Created to offer potential and current end users and owners of industrial steel storage racks a high-level, visual introduction into the key considerations of rack system selection, RMI has produced and released a new video: “Specifying and Selecting Your Rack ...

Why Are There Two R-Mark Certifications, One For Rack And ...

Offered as two separate certifications to manufacturers of industrial steel storage racks and of welded wire rack decking, RMI’s R-Mark assures storage rack users that the rack frame, beam and decking capacities shown in a unique design’s load table were ...

Safety Tips For Ensuring The Structural Integrity Of Drive-In And ...

Drive-in rack and drive-through rack both provide high-density pallet storage with fewer aisles. Comprised primarily of vertical upright frames, horizontal support arms, and horizontal load rails—both are typically used for one-wide by multiple-depth storage. In a drive-in configuration, all loading ...