Planning Your Rack System- Part 1

With myriad options to choose from, this explainer will help you zero in on the right system for your operations. Every distribution center and manufacturing operation relies on racking. While that’s a given, the various configurations and options of racking ...

The “Dos And Don’ts” Of Pushback Rack

Engineered to store pallet loads on both sides of an aisle, industrial pushback racking storage systems deliver cubic densities that are approximately 25% to 65% greater than selective racking. The systems are built with a series of nested carts that ...

How Pallets Contribute To The Safe Use Of Pushback Rack ...

As with the vast majority of industrial steel storage rack systems, last-in/first-out (LIFO) pushback racking systems are designed for use with specific pallet types, loads and rack configurations. Operators, therefore, should be trained to only load a pushback system with ...

Learn How To Design The Optimal Rack System For Traditional ...

With traditional retail distribution relying on full pallet movement and/or picked cases, while e-commerce distribution is typically comprised of reserve, full pallet storage used to replenish a pick module or other each picking system, it stands to reason that each ...

Why Are Pallets Important For Pushback System Safety?

Last-in/first-out (LIFO) pushback racking systems (like the vast majority of industrial steel storage rack systems) are designed for use with specific pallet types, loads and rack configurations. For that reason, it is critically important to ensure that operators only load ...

Recommended Safety Practices For Case Picking Of Products Stored In ...

Because they support high-throughput order fulfillment of single product—typically fast movers—some operations utilize pushback racking storage systems as part of their picking process. In order to ensure that pickers are able to perform their assigned tasks safely when working with ...

The Safest Way To Unjam A Pushback Rack System

Even though the wheeled carts in industrial pushback racking storage systems are designed to travel smoothly backward and forward from the point of pallet insertion and removal, jams can sometimes occur. Common causes of hang-ups include improper loading of pallets, ...

Best Practices In Safe Operation Of Pushback Rack

Industrial pushback racking storage systems are engineered to store pallet loads on both sides of an aisle at higher cubic densities approximately 25% to 65% greater than selective racking. That’s because these systems are built with a series of nested ...

RMI Seminar At ProMat To Address Rack Safety In The ...

With the holiday shopping season officially starting a week ago on Black Friday (or—in some cases—a week or two prior, as retailers offered special discounts ahead of Thanksgiving to get a jump on the competition for consumers’ dollars), the popularity ...

Newest Racking Technologies And How To Pick The Safest Solution ...

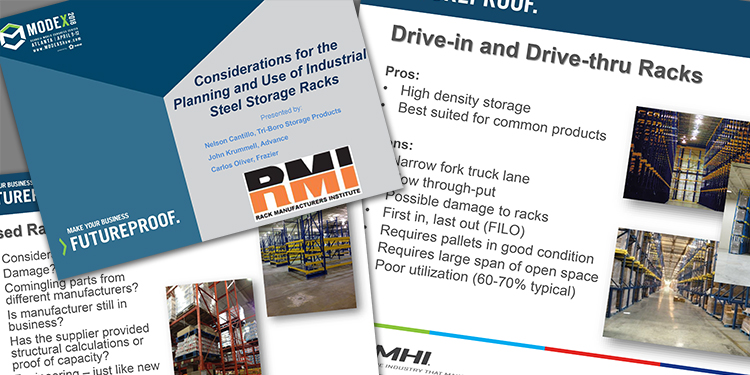

During MODEX 2018, held this past April in Atlanta, members of RMI presented a free, on-floor seminar to attendees. Entitled “Considerations for the Planning and Use of Industrial Steel Storage Racks,” the 40-minute session’s slides and audio were recorded for ...