Why Are There Two R-Mark Certifications, One For Rack And ...

Offered as two separate certifications to manufacturers of industrial steel storage racks and of welded wire rack decking, RMI’s R-Mark assures storage rack users that the rack frame, beam and decking capacities shown in a unique design’s load table were ...

Safety Tips For Ensuring The Structural Integrity Of Drive-In And ...

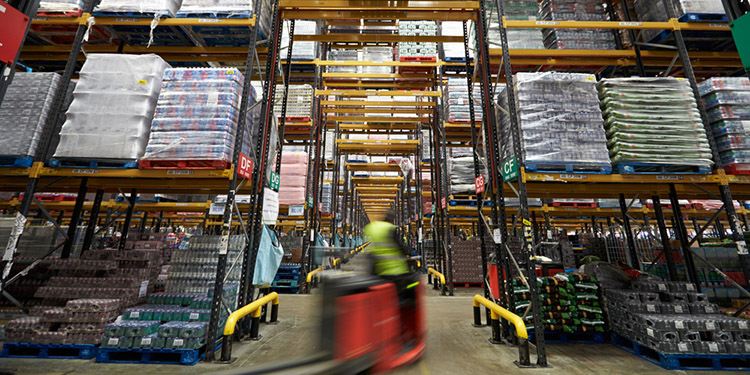

Drive-in rack and drive-through rack both provide high-density pallet storage with fewer aisles. Comprised primarily of vertical upright frames, horizontal support arms, and horizontal load rails—both are typically used for one-wide by multiple-depth storage. In a drive-in configuration, all loading ...

Why Your Rack Installation Needs Load Beam Locking Devices

For the safety of the racking structure and the persons and machinery working in and around it, RMI’s ANSI MH16.1-2012: Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks calls for the installation of beam locking devices ...

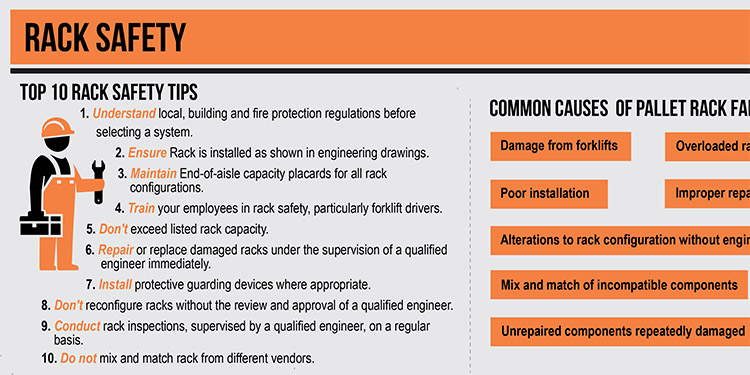

RMI Infographic Highlights Rack Safety With Tip Sheet

RMI’s new Rack Safety Infographic offers a quick, visual guide to best practices in industrial steel storage rack safety. Designed as an interactive PDF and intended for owners, facility managers and users of all types of storage rack, the document ...

Welded Wire Rack Decking: Safety Fundamentals

Considered an accessory to industrial steel storage rack, welded wire rack decking is placed on pallet rack beams to span the distance between them. They provide additional support for items stored a pallet, prevent items from falling through the racking, ...

More Frequent Rack Inspections: Your New Year’s Resolution

Committing to regularly inspecting storage rack at routine intervals is key to ensuring the safety and performance of a racking system within a facility. But how often should those inspections be performed, and by whom? The answer to those questions ...

Why Does Pallet Rack Need To Be Straight And Plumb?

A pallet rack column that is leaning (out-of-plumb) or bowed (out-of-straight) beyond a certain point will have a significantly reduced capacity, making it unsafe and at risk of collapse. RMI defines the severity of these two conditions as follows: Out-of-Plumb ...

Mix Racking From Different Manufacturers At Your Own Risk

In many cases, rack collapses are caused by unsafe mixing and matching of incompatible components from different manufacturers (also known as “intermembering”). If a rack column or beam is damaged, an owner might erroneously believe that it can be replaced ...

Repair The Rack System Versus Repair The Damaged Component

Rack systems’ appearance is deceptively simple. Uprights and beams form a framework that holds pallets with loads of product; to the casual observer, these systems don’t look overly complex. So if a rack component is damaged, it should just be ...

Field Welding Versus Bolt Repair For Damaged Pallet Rack

Upon discovering and identifying that damage has occurred to a pallet rack column, frame or beam, in some cases the fastest and most affordable repair approach might appear to be field welding. That is, an on-site maintenance technician attempts to ...