The Ins and Outs of Pallet Rack Anchoring

Anchoring is required and essential. Here’s what you need to know. Your racking systems are the heart of your warehousing storage, and ensuring safe use is essential. In most cases, racking holds multiple tons of pallets, representing thousands upon thousands ...

Pairing Pallets and Racking

Before making any rack purchase, it’s important to understand the type and condition of your pallets. You’ve got a big investment in your racking system, so you want to get it right. One of the biggest considerations when choosing your ...

Planning Your Rack System

With the right combination of equipment, you can meet your varied customers’ needs. The complexity of warehousing operations has been on a steady increase for the past decade or so. Now add in the pandemic and explosive demand for ecommerce, ...

Can A Damaged Rack Be Repaired While Still Loaded?

Upon discovering that damage has occurred to industrial steel storage rack, the best practice is to immediately remove the structure from service and safely unload all stored pallet loads. This significantly reduces the risk of a collapse and the potential ...

Why Column Base Plates Provide A Solid Foundation For Rack ...

When a damaged rack column is replaced or repaired, the state of the base plate (sometimes called foot plates) at the bottom of the column must also be assessed. Base plates are included at the bottom of every rack upright ...

Best Practices For Rack Repair Column Splices

As one of the most exposed components of industrial steel storage rack, columns are particularly vulnerable to damage — frequently from a forklift or pallet load impact. When a damaged rack upright is discovered, the system owner must decide between ...

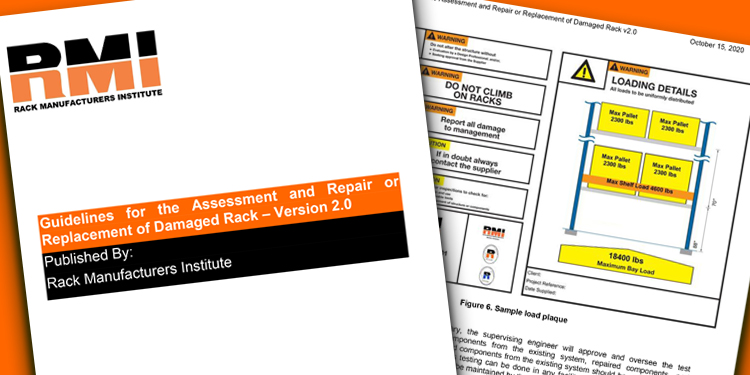

Updated Rack Repair Guidelines Released by RMI

The Rack Manufacturers Institute (RMI) has updated its existing publication, Guidelines for the Assessment and Repair or Replacement of Damaged Rack, with the latest information as a reference for owners and users of industrial pallet rack systems. The latest release, ...

Building Codes And Rack Repair: What You Need To Know

The majority of jurisdictions in the U.S. have adopted the International Code Council’s International Building Code (IBC) as their base code standard governing the safe design and construction of building structures. The IBC references RMI’s ANSI MH16.1: Specification for the ...

Why A Bolted Repair Of Damaged Pallet Rack May Be ...

When damage to an industrial steel pallet rack system column or frame has been discovered, RMI’s publication “Guideline for the Assessment and Repair or Replacement of Damaged Rack – Version 2” suggests multiple options for repairing the damage. Among the ...

Should A Damaged Rack Component Be Repaired Or Replaced?

Rack may become damaged. With forklift drivers maneuvering through industrial steel storage rack aisles with heavy pallet loads of product, it’s not unusual for the rack to be on the receiving end of an impact. But after a damaged rack ...