Rack Codes & StandardsRack Design & InstallationRack Inspection & MaintenanceRack Repair & ReconfigurationUncategorized

A Look at ANSI MH32.1

In order to safeguard your employees on elevated work surfaces, you’ll need to follow these standards. In the warehouse, much of your employee’s work will take place in overhead work areas that are designed to maximize the vertical space you ...

Retrofitting Racks for Individualized Picking

The nature of picking is changing and your operations may need to change with it. With the explosion of ecommerce over the past few years, warehouses that were not set up for picking eaches must find configurations that allow picking ...

Nine Benefits Of Rack Repair Kits

Pallet rack damage happens, often due to an impact from a forklift as it transports a load through the facility. Upon identification of a damaged rack section the structure should be isolated, and a qualified, professional rack engineer should be ...

Is It Okay To Cut Pallet Rack Uprights?

Sometimes a rack owner will decide to relocate an existing pallet rack structure to a different location within the same facility — only to discover that the new space has a lower ceiling height than the original site. If only ...

The “Dos and Don’ts” of Reconfiguring Pallet Rack

Most pallet rack is manufactured for adjustability and assembly in multiple configurations, which might lead a system owner or user to assume a current installation can be reconfigured safely to increase storage density. While making such changes to racking, such ...

Can A Damaged Rack Be Repaired While Still Loaded?

Upon discovering that damage has occurred to industrial steel storage rack, the best practice is to immediately remove the structure from service and safely unload all stored pallet loads. This significantly reduces the risk of a collapse and the potential ...

Why Column Base Plates Provide A Solid Foundation For Rack ...

When a damaged rack column is replaced or repaired, the state of the base plate (sometimes called foot plates) at the bottom of the column must also be assessed. Base plates are included at the bottom of every rack upright ...

Best Practices For Rack Repair Column Splices

As one of the most exposed components of industrial steel storage rack, columns are particularly vulnerable to damage — frequently from a forklift or pallet load impact. When a damaged rack upright is discovered, the system owner must decide between ...

Why You Shouldn’t Mix Rack Components From Different Manufacturers In ...

While rack columns and beams constructed by different manufacturers may appear similar, mixing components in the same structure — also sometimes called “intermembering” — is unsafe and not recommended. That’s because connecting incompatible rack components, which can erroneously occur as ...

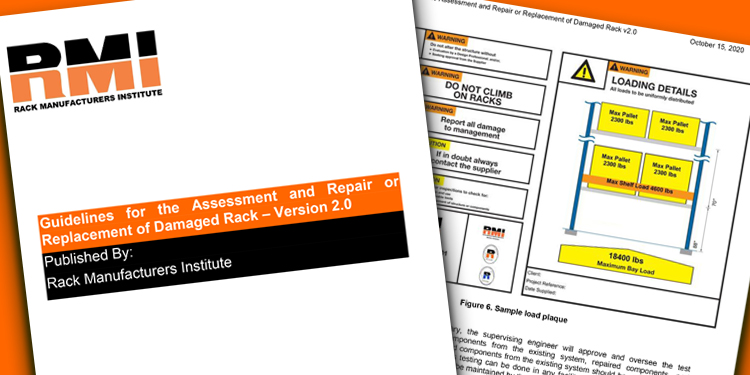

Updated Rack Repair Guidelines Released by RMI

The Rack Manufacturers Institute (RMI) has updated its existing publication, Guidelines for the Assessment and Repair or Replacement of Damaged Rack, with the latest information as a reference for owners and users of industrial pallet rack systems. The latest release, ...