Rack Design Best Practices For Food Storage

No two rack designs are alike. That statement is particularly true for warehouses and distribution centers handling food. For safe and efficient storage of perishables, shelf-ready, or frozen products, the design, layout, construction, and finish of pallet rack must meet ...

Rack Safety Nets And Panels Stop Products From Falling, Part ...

As detailed in a previous post, rack netting and steel mesh containment panels mitigate the forces of gravity. Installed directly on the rack, these protective guarding solutions catch items that tumble from the upper levels of pallet rack. This reduces ...

Rack Safety Nets And Panels Stop Products From Falling, Part ...

Industrial steel storage rack is a great solution for maximizing overhead usable space in warehouses and distribution centers. But, thanks to gravity, storing items above floor level increases the risk of products tumbling to the ground. In addition to inventory ...

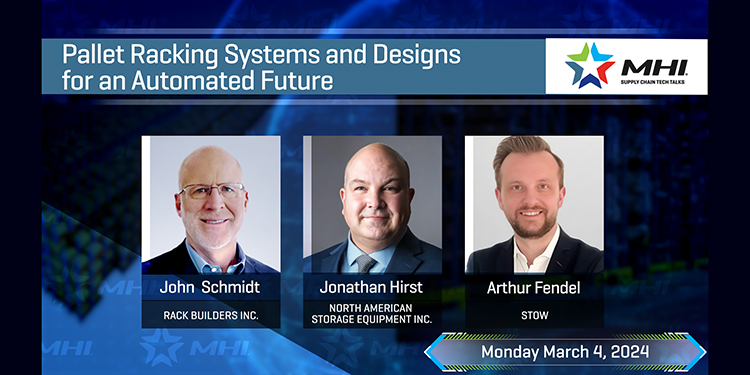

March 4 MHI Tech Talk Explores Integrating Racks With Automation

Pallet racking systems are virtually ubiquitous in warehouses, distribution centers, and fulfillment operations worldwide. Automation, on the other hand, is less so. Yet, with the persistent shortage of available workers, more of these facilities are evaluating automated solutions. Prior to ...

Learn About Storage Rack Safety And Automation Integration At MODEX ...

Have questions about the safe design and use of pallet rack? Wondering how to successfully integrate industrial racking with automation? Answers to both questions can be found in two separate MODEX on-floor education sessions. Participating attendees will learn about both ...

Don’t Miss The Latest Rack Safety Solutions At MODEX 2024

Atlanta’s Georgia World Congress Center will host more than 900 exhibitors at MODEX this year — March 11-14, 2024. That’s a lot of material handling equipment to explore! If you’re specifically looking for new rack safety products, however, be sure ...

Last Mile Delivery: How To Arrange Rack For Success

E-commerce sales continue to grow. The latest figures from the U.S. Census Bureau found that online shopping increased 7.6% year-over-year in Q3 2023, accounting for 15.6% of total sales. As a result demand for last mile delivery — the movement ...

Key Factors To Consider When Designing A Warehouse Rack Layout

Whether equipping a new distribution center (DC) or outfitting an expansion to an existing warehouse, it’s critical to get the pallet rack layout right before product is loaded into it. An incorrect layout might impede access to inventory or hinder ...

Compact Rack Solutions Increase Warehouse Capacity

Demand for additional warehouse space continues to rise. According to warehouse developer Prologis, “for every dollar of U.S. gross domestic product, at least 20% more logistics space is needed than was the case before the COVID-19 pandemic.” Prologis attributes this ...

Answer These 4 Rack Specification Questions To Source Your Optimal ...

When planning for a new warehouse or distribution center, there are many factors to consider. Among them are the designated storage areas and different methodologies used to hold inventory. For operations looking to maximize the cube of their building, industrial ...