Cantilevered Storage Rack Safety 101

Cantilevered rack structures are comprised primarily of a central, vertical column from which horizontal arms project perpendicularly on one or both sides, with no vertical column connecting the arms on the aisle face. Either free standing or top-tied, these racks ...

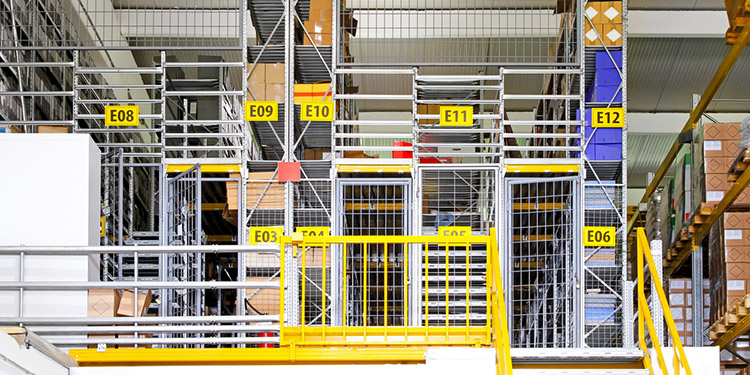

Protecting Workers on Rack Supported Platforms, Pick Modules

To keep workers safe when picking items stored at levels above the facility floor—such as in pick modules or on shelving within rack supported platforms—guidelines are offered in RMI’s ANSI MH16.1-2012: Specification for the Design, Testing and Utilization of Industrial ...

Why Horizontal Clearance Is Important In Seismic Rack Installations

When an earthquake happens, the ground moves. And, shortly thereafter, any vertical structures on top of the shaking ground move too. That includes both the walls and support columns of a warehouse, and the storage rack inside those structures. In ...

Understanding Fire Sprinkler Codes And Rack Design

No one wants a fire in their warehouse. Yet they happen every year. According to statistics from the National Fire Protection Association (NFPA): U.S. fire departments respond to an estimated average of 1,210 fires in warehouses annually. These fires result ...

RMI’s New Video Offers Introduction To System Selection

Created to offer potential and current end users and owners of industrial steel storage racks a high-level, visual introduction into the key considerations of rack system selection, RMI has produced and released a new video: “Specifying and Selecting Your Rack ...

Why Are There Two R-Mark Certifications, One For Rack And ...

Offered as two separate certifications to manufacturers of industrial steel storage racks and of welded wire rack decking, RMI’s R-Mark assures storage rack users that the rack frame, beam and decking capacities shown in a unique design’s load table were ...

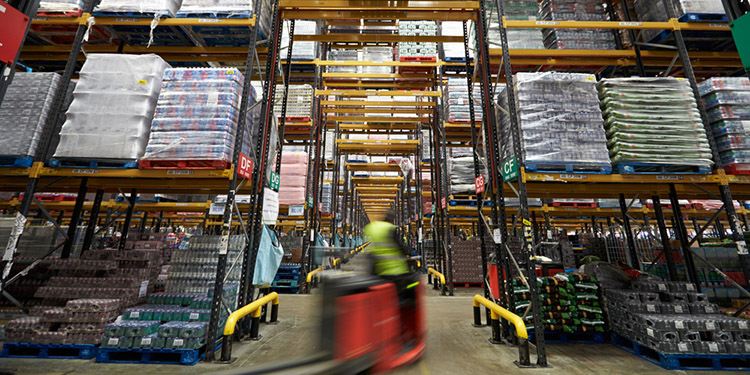

Safety Tips For Ensuring The Structural Integrity Of Drive-In And ...

Drive-in rack and drive-through rack both provide high-density pallet storage with fewer aisles. Comprised primarily of vertical upright frames, horizontal support arms, and horizontal load rails—both are typically used for one-wide by multiple-depth storage. In a drive-in configuration, all loading ...

Why Your Rack Installation Needs Load Beam Locking Devices

For the safety of the racking structure and the persons and machinery working in and around it, RMI’s ANSI MH16.1-2012: Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks calls for the installation of beam locking devices ...

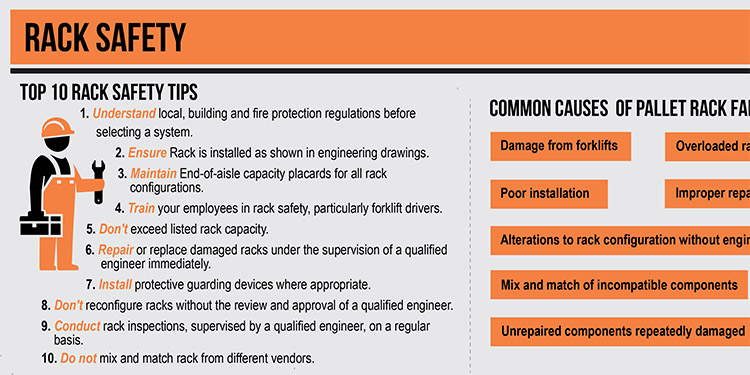

RMI Infographic Highlights Rack Safety With Tip Sheet

RMI’s new Rack Safety Infographic offers a quick, visual guide to best practices in industrial steel storage rack safety. Designed as an interactive PDF and intended for owners, facility managers and users of all types of storage rack, the document ...

Welded Wire Rack Decking: Safety Fundamentals

Considered an accessory to industrial steel storage rack, welded wire rack decking is placed on pallet rack beams to span the distance between them. They provide additional support for items stored a pallet, prevent items from falling through the racking, ...