Building Codes And Rack Repair: What You Need To Know

The majority of jurisdictions in the U.S. have adopted the International Code Council’s International Building Code (IBC) as their base code standard governing the safe design and construction of building structures. The IBC references RMI’s ANSI MH16.1: Specification for the ...

Why A Bolted Repair Of Damaged Pallet Rack May Be ...

When damage to an industrial steel pallet rack system column or frame has been discovered, RMI’s publication “Guideline for the Assessment and Repair or Replacement of Damaged Rack – Version 2” suggests multiple options for repairing the damage. Among the ...

Should A Damaged Rack Component Be Repaired Or Replaced?

Rack may become damaged. With forklift drivers maneuvering through industrial steel storage rack aisles with heavy pallet loads of product, it’s not unusual for the rack to be on the receiving end of an impact. But after a damaged rack ...

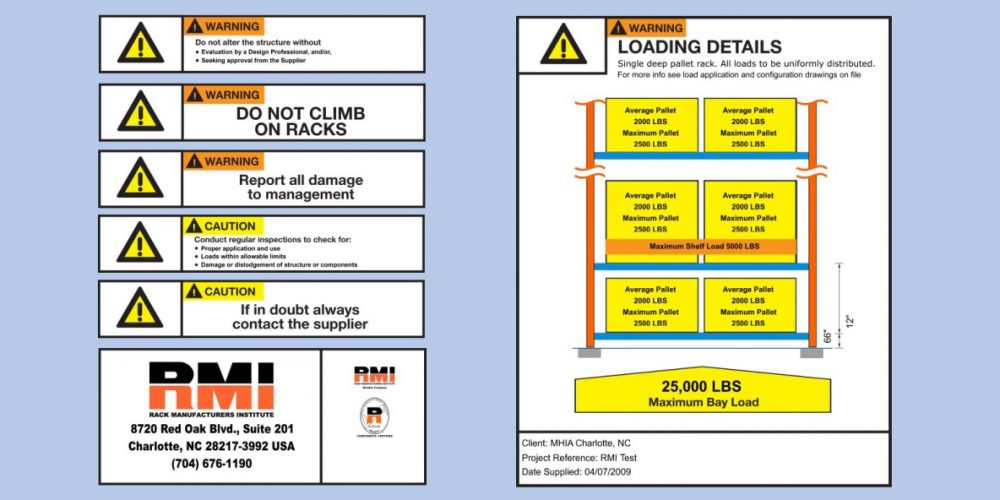

Use Rack Load Capacity Plaques And LARC Drawings For A ...

To ensure a safer, and, therefore, more productive operation, owners of industrial steel storage racking are responsible for posting rack load capacity plaques in conspicuous locations, and should refer to the system manufacturer’s load application and rack configuration (LARC) drawings ...

Why Mixing Rack Components From Different Manufacturers Is A Bad ...

Pallet rack beams and columns from different manufacturers — while they may appear similar — in fact are not. Therefore, it is never a good idea to mix-and-match components from different racking systems within a single structure. The reason? Doing ...

Before Relocating Or Reconfiguring Rack Watch RMI’s New Safety Video

To keep up with changing customer expectations and handling needs, facilities are changing faster than ever before. Because of its inherent flexibility, operations might be taking a closer look at their current industrial steel storage rack installation and considering either ...

Rack Repair Kits: What You Need To Know

When a damaged rack section is assessed by a qualified, professional rack engineer, it may be determined that a repair can be completed with a rack repair kit as opposed to field welding. That’s because, as outlined in Appendix 1 ...

The Basics Of Storage Rack Safety Detailed In RMI’s ProMat ...

At ProMat 2019, held this past April in Chicago, members of RMI presented a free, on-floor seminar to attendees. Entitled “Storage Rack Safety 101,” the 35-minute session’s slides and audio were recorded for those who were unable to attend, or ...

Ensure Rack Safety By Using A Professional For Post-Installation Inspections

Although day-to-day routine inspections of storage rack should be conducted by facility owners and employees to identify damaged areas—regardless of the severity—it’s also a good practice to engage an independent professional rack engineer to review the system. These professional reviews ...

RMI’s New Video Overviews The Basics Of Rack Maintenance And ...

RMI has produced and released a new video offering some basic guidelines for inspecting, maintaining and repairing industrial steel storage rack systems to ensure a safe working environment. The video is targeted to both potential and current end users and ...