Mobile Automated Vehicles, Pallet Rack Selection, And Design

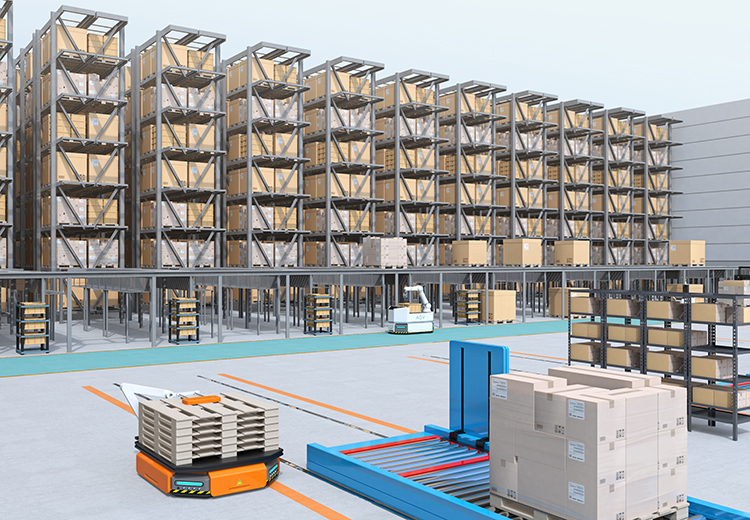

Advances in mobile automated vehicle technology is making the practicality of deploying them in warehouses and distribution centers more feasible. These solutions include autonomous mobile robots (AMRs), automatic guided vehicles (AGVs), and self-driving forklifts. Indeed, forecasts predict the market for these solutions will reach $8.7 billion by 2028. With that growth trajectory in mind, now is the time for facility operators considering mobile automated vehicles to plan for their pallet rack selection and design needs.

What are Mobile Automated Vehicles?

Mobile automated vehicles can navigate throughout an operation without any human intervention. To do this, they utilize a variety of different sensors. These include cameras, LIDAR, radar, and ultrasonic devices that collect information about the vehicle’s location and operating environment.

The sensors enable each vehicle to learn its surroundings and detect obstacles — including personnel, racking, and other building features. When a mobile autonomous vehicle identifies something in its travel path, it can slow, stop, or change direction. Vehicles can also dynamically adapt to changes in their surroundings as they handle and transport loads.

What are the Benefits?

There are a variety of benefits to warehouses and distribution centers adding AMRs, AGVs, or self-driving forklifts, said Arthur Fendel. Fendel is Vice President of Sales and Engineering at STOW, a member of the Rack Manufacturers Institute (RMI).

“First, these vehicles can improve the accuracy and precision of inventory movement within an operation. That’s thanks to the sensors on mobile automated vehicles which detect an obstacle and stop prior to an impact,” he said. “This level of navigational accuracy can contribute to a safer work environment for people, products, and equipment.”

The addition of mobile automated vehicles for routine transport of inventory from storage to forward pick zones, for example, allows managers to assign workers to other, more value-added tasks within an operation. Further, use of automation can lead to a reduction in workplace incidents. That’s because their navigational controls reduce the risk of human error. The vehicles also offer the opportunity to remove personnel from potentially hazardous conditions.

With regard to pallet rack design, “the precision navigation of mobile automated vehicles is so reliable that often the aisle spacing between rows can be tighter,” Fendel added. “This allows a rack engineer to potentially add more racking to the design. That, in turn, increases the overall storage capacity of the operation.”

Selection and Design of Rack for Mobile Automated Vehicles

However, the sensors used by mobile automated vehicles to aid in the placement and removal of a pallet loads within the rack demand high production tolerances on both beams and uprights.

“If the rack structure is weak or overloaded, any bowing, sagging, or leaning of the beams and columns could interfere with the vehicle sensors’ ability to accurately anticipate the obstacle. These conditions also compromise the safety of the racking structure,” Fendel explained. “To ensure that racking systems comply with building codes and meet the correct standards, the rack’s engineering should follow standards published by RMI. These include ANSI MH16.1, Design, Testing, and Utilization of Industrial Steel Storage Racks and ANSI MH26.2, Design, Testing, and Utilization of Industrial Storage Rack Decking.”

To further confirm the industrial storage rack meets applicable standards, purchasers should look for manufacturers who are R-Mark certified. This certification provides independent verification that the rack manufacturer meets applicable standards in its design, engineering, and manufacturing processes.

Considerations when Deploying Mobile Automated Vehicles in Existing Rack

For operations deploying mobile automated vehicles within an existing rack structure, Fendel said minor infrastructure adjustments might be advisable.

Damaged rack — such as bent components — should be repaired or replaced; these can interfere with the sensors’ functioning and overall rack system integrity. If it is necessary to modify the rack system to accommodate vehicle travel paths, consult the rack’s design engineer for guidance and approval prior to making any changes.

Additionally, although mobile automated vehicles will slow or stop for personnel in their path, for the sake of safety and efficiency it’s best to separate the two.

“Best practice is to define vehicle driveways and personnel walkways,” Fendel added. When necessary, such as in high-traffic areas, install guardrails and other applicable protective guarding equipment. Prior to implementation, the facility should conduct a risk assessment to secure appropriate and applicable risk reduction solutions for their facility.”

Learn More About Deploying Automation with Racking

Looking for more best practices when integrating industrial storage rack with automation? View the recording of a recent MHI Tech Talk, “Pallet Racking Systems and Designs for an Automated Future.” Additionally, the members of RMI are available for consultations, insights, and recommendations. Visit mhi.org/rmi for additional details.