Load Handling And Elevated Work Platforms: How To Ensure Safe Access For Pallet Loading And Removal

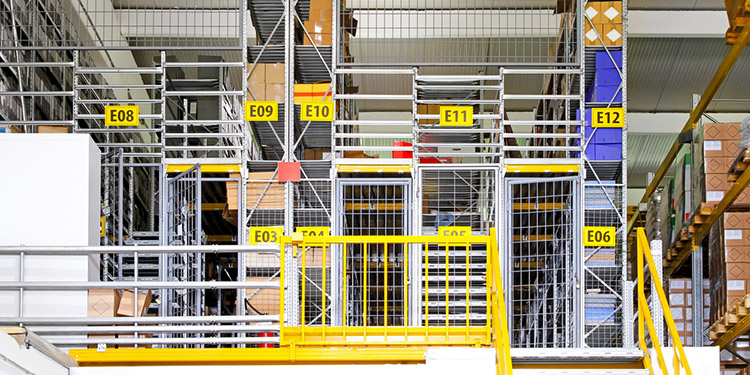

To replenish pallets of product picked by associates working in pick modules or on rack supported platforms, most facilities use forklifts to deliver the loads to a pallet drop zone at an aisle-side ledge. While guardrails are required by the ANSI MH16.1-2012: Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks (published by RMI) to provide fall protection around the perimeter of the elevated platforms or walkways, the standard also allows for mechanisms that can be temporarily removed to enable this access.

In section 8.4.3.1 of the ANSI MH16.1-2012 standard, “Guardrail Requirements,” several alternatives are offered to provide accessibility yet still preserve employee safety, provided that the devices match the strength and configuration requirements of the adjacent permanent guardrail. Further details can be found in section 5.1 of the ANSI MH32.1-2018: Stairs, Ladders, and Open-Edge Guards for Use with Material Handling Structures, a standard developed by RMI in partnership with the Storage Manufacturers Association (SMA). Its provisions specifically apply to industrial racking pick modules; decked-over platforms; industrial shelving pick modules and decked-over platforms; and free-standing work platforms.

Temporary guarding options include:

- Safety gates that either swing open to one side or that consist of two interconnected protective barriers that raise, lower, slide, or pivot in tandem.

- Removable guardrail sections, which must be equipped with a personal fall-protection system.

- Removable chains or cables for pallet drop zones, which must also be equipped with a personal fall-protection system.

Additionally, as a best practice to further protect the elevated platform structure and the workers situated upon it, forklift operators should be trained to approach these loading and unloading areas with caution, as well as to alert personnel working overhead that pallet placement or removal is imminent. For increased visibility, the beams at this elevated drop zone opening can be painted a different color—such as red or yellow—to help forklift drivers more accurately place or retrieve the load.

Need additional information about other structural elements that protect workers on pick modules? Download a free copy of the RMI/SMA ANSI MH32.1-2018: Stairs, Ladders, and Open-Edge Guards for Use with Material Handling Structures specification, here.