What’s Height-To-Depth Ratio, And Why Is It Important?

To significantly minimize the risk of a single row of standard steel storage rack from becoming unstable and overturning due to a seismic event, wind or forklift impact, Section 8.1 of RMI’s ANSI MH16.1-2012: Specification for the Design, Testing and ...

Don’t Forget To Check Permitting Requirements For Your Proposed Rack ...

Whether planning for a new rack system in a new location, or a new rack system in an existing location, the system cannot be installed until all applicable building codes have been satisfied. Further, a building permit must be issued ...

Making A Tight Beam-To-Column Connection

To ensure that a pallet rack beam does not separate from an upright rack column as a result of either an impact or seismic event, RMI’s ANSI MH16.1-2012: Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks ...

Why Was The R-Mark Created?

As a voluntary program for manufacturers of industrial steel storage racks and of welded wire rack decking, RMI’s R-Mark Certification helps to assure storage rack users that they have selected a product designed, engineered and made by a reputable supplier. ...

Safe Spacing Matters: Pallet Load Clearance Recommendations For Storage Rack

To minimize the risk of a pallet load and/or handling equipment colliding with a rack column or another load—creating an unsafe situation—storage rack design engineers incorporate a space allowance around the widest part of the load envelope when calculating the ...

Pallet Beam Deflection: How Much Is Acceptable?

When the specifications for a pallet support beam are determined by a qualified rack design engineer, the maximum amount of deflection—or bowing—permissible is included in the calculations as noted in Section 5.3 of RMI’s ANSI MH16.1-2012: Specification for the Design, ...

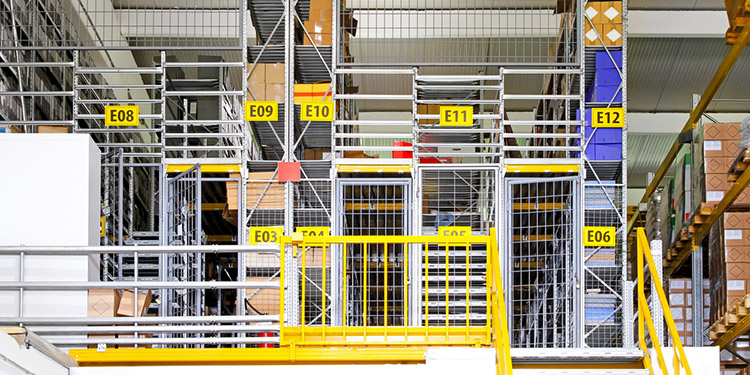

Protecting Workers on Rack Supported Platforms, Pick Modules

To keep workers safe when picking items stored at levels above the facility floor—such as in pick modules or on shelving within rack supported platforms—guidelines are offered in RMI’s ANSI MH16.1-2012: Specification for the Design, Testing and Utilization of Industrial ...

Why Horizontal Clearance Is Important In Seismic Rack Installations

When an earthquake happens, the ground moves. And, shortly thereafter, any vertical structures on top of the shaking ground move too. That includes both the walls and support columns of a warehouse, and the storage rack inside those structures. In ...

Why Are There Two R-Mark Certifications, One For Rack And ...

Offered as two separate certifications to manufacturers of industrial steel storage racks and of welded wire rack decking, RMI’s R-Mark assures storage rack users that the rack frame, beam and decking capacities shown in a unique design’s load table were ...