» Read more recent posts about seismic calculations, seismic rack designs, and the latest version of ANSI MH16.1.

Seismic design rack is not just on the West Coast anymore.

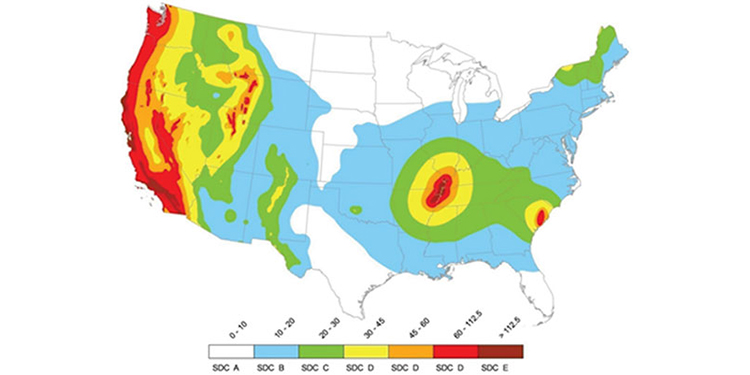

Depending on where within the U.S. a facility is located, seismic design considerations may need to be taken into account when engineering, manufacturing, and installing a pallet rack system. While this is especially prevalent on the West Coast, it can also apply in other areas such as Memphis, Tennessee and Charleston, South Carolina.

The subsequent design decisions—all intended to increase the safety of any persons in proximity to a rack by reducing the risk of its collapse should an earthquake occur—are a result of a series of engineering calculations.

ANSI MH16.1 Offers Seismic Rack Calculations

RMI’s ANSI MH16.1: Design, Testing and Utilization of Industrial Steel Storage Racks includes a complete listing of the calculations a qualified rack design engineer will perform. Considerations include:

- Geographic region, denoted by Seismic Design Categories (SDCs), which range from A to F.

- Specific site location contours and subsequent design parameters. These are available via the United States Geological Survey (USGS) website.

- Soil classification.

- Supporting concrete slab thickness.

Generally speaking, rack engineered to meet seismic safety requirements has a thicker and larger base plate. Sometimes called a foot plate, base plates enable the anchoring of each column to the floor. Each manufacturer configures a base plate that best protects a rack installation. Sizes can include 5 x 5, 6 x 6, 4 x 8, 5 x 8 or 6 x 8 inches, and in thicknesses ranging from 0.25- to 0.375-inch.

Seek Professional Engineering Guidance

Further, a rack system designed for a seismic application will typically be much heavier than one engineered for a low seismic application. Regardless of your facility’s location, be sure to select a well-qualified professional engineer with pallet rack experience. This person will also oversee the design and permitting of your system.

Want to learn more about seismic design and rack safety? RMI includes a section on Seismicity in its list of Frequently Asked Questions.