At ProMat 2025, automation wasn’t just a buzzword — it dominated both the show floor and the conversation. In recognition of this trend, the Rack Manufacturers Institute (RMI) shared a free, on-floor educational session: “Pallet Racking Systems and Design for an Automated Future.” The presentation explored how modern warehouse operations are evolving, and why rack automation is central to that evolution.

A trio of RMI experts shared the podium:

- Chris Aprile, Senior Structural Engineer at RMI member Steel King Industries

- Bill Edgy, Director of National Accounts at RMI member Automha Americas Automation Corp.

- Carlos Oliver, President of RMI member Frazier Industrial Co.

The panel covered the foundational elements of racking systems, explored the transition into semi- and fully-automated storage, and spotlighted the latest in four-way shuttle technology. Their message? Rack automation is quickly becoming an essential component of today’s modern warehousing operations.

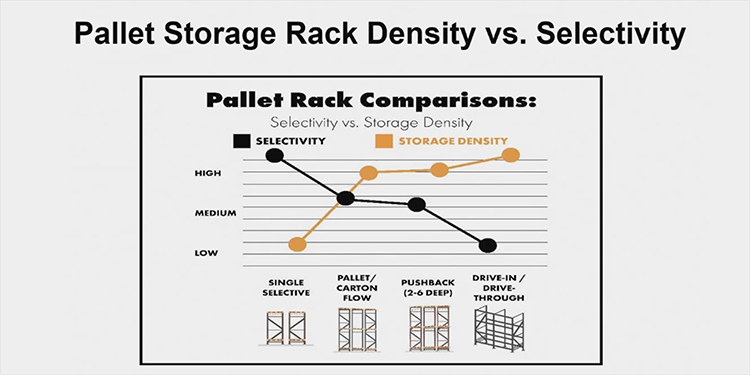

Selectivity Inversely Proportional to Storage Density

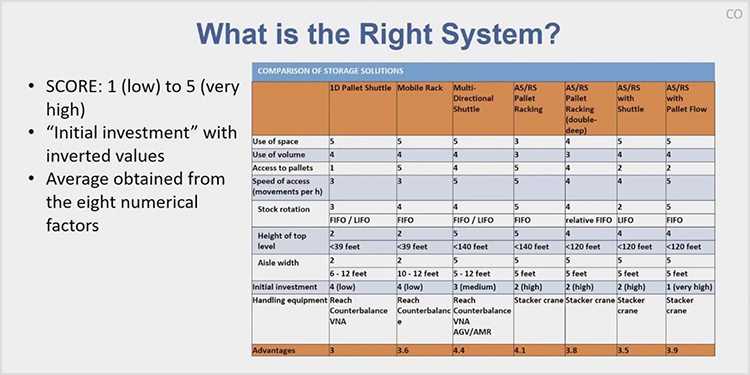

Aprile began the session by framing the core differences between racking types. He also explained how each rack style impacts automation design. He discussed key points such as inventory accessibility and storage methodologies such as first-in/first-out (FIFO) and last-in/first-out (LIFO) systems.

“Think about your warehouse and how you lay things out in the beginning phases,” he noted. “One of the most important things is figuring out what type of rack system you want to use.”

Aprile explained how warehouse operators must weigh selectivity against density. That is, the tradeoff between accessibility to stored pallet loads and the amount of material that a rack system can hold.

“Selective racking offers the highest accessibility. Denser systems like drive-in racks or pallet flow are more compatible with high-volume, repetitive stock keeping units (SKUs),” he said. “This can be especially important when planning for rack automation.”

Rack Automation is a Lifelong Investment

In the second portion of the presentation, Oliver emphasized that transitioning from manual to automated systems is not just a technical shift — it’s an organizational one.

“Going from a manual system to a fully automated one is a big cultural change,” Oliver noted. “You need the internal resources, the people, and the planning mindset to make that leap.”

He encouraged companies to future-proof their rack automation investment by prioritizing scalability. “The way you’re running your business now may not be how you’re running it 10 or 15 years from now,” said Oliver.

He also explained how automated storage and retrieval systems (AS/RS) require far more precise tolerances than traditional racking. “Manual racking is not suitable for automation,” he stressed. “It must be aligned to a common datum point because automation works off sensors, not visual cues.”

Additionally, Oliver urged attendees to stay ahead of evolving fire codes, especially those impacting deeper lane automated racking.

Four-Way Shuttle Systems: The Newest Rack Automation Innovation

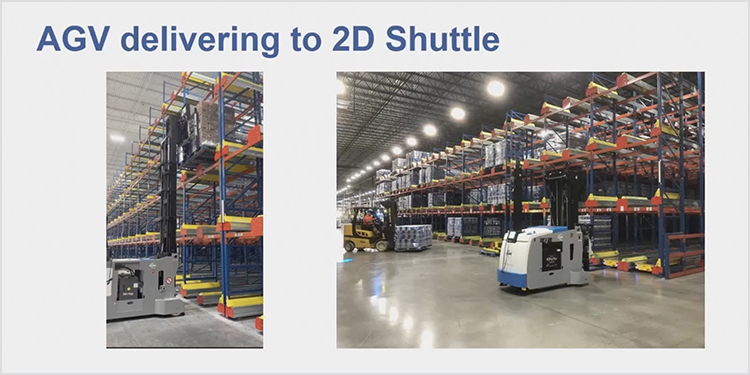

Edgy walked session participants through the latest innovation in rack automation: four-way shuttle systems. By allowing simultaneous movement on multiple levels and axes, these systems greatly increase both throughput and redundancy.

“Four-way shuttles provide maximum storage density and comprehensive efficiency,” said Edgy. “Also, if one shuttle or level goes down, others can still operate. That’s the kind of uptime operations expect from automation.”

Unlike traditional stacker crane systems, four-way shuttles offer flexibility in handling varying pallet sizes. They are also easily maintained without halting warehouse operations. This makes them ideal for fast-scaling operations that need rack automation to stay agile.

Rack Automation: A Big Investment with a Bigger Payoff

In the Q&A portion of the session, Edgy addressed common rack automation investment hesitations. “The initial investment in automation is high,” he agreed. “But when you consider productivity, labor savings, accuracy, and safety, it quickly pays for itself.”

Edgy further pointed out that smart companies repurpose workers into roles that support automation. “With the right training, employees can operate and maintain these systems. You’re not eliminating jobs, you’re enhancing them,” he observed.

Aprile also circled back to the importance of scalability in rack automation. “You don’t have to go fully automated overnight,” he said. “Starting with something like a pallet runner gives an operation a way to evolve incrementally.”

Key Takeaways for Warehouse Automation Decision-Makers

For operations evaluating how to make a warehouse smarter and more resilient, the presenters offered guidance for making rack automation central to that strategy. Tips included:

- Choose racking systems based on long-term throughput and inventory goals.

- Understand that automated systems need tighter tolerances and structural planning.

- Plan ahead for fire code requirements and future retrofitting needs.

- Explore semi-automated solutions like pallet runners as an initial step into automation.

- Invest in modular, scalable rack automation.

- Prepare the current workforce through training and role evolution.

A recording of the “Pallet Racking Systems and Design for an Automated Future” session is available. For more insights into rack automation, listen to the Aprile, Edgy, and Oliver in a recent RMI podcast, and visit RMI’s website, mhi.org/rmi.