Two Educational Sessions Focus On Warehouse Rack Safety At ProMat 2023

Looking for insights into the safe design and utilization of industrial steel storage rack? Look no further than ProMat 2023, where members of the Rack Manufacturers Institute (RMI) will present separate education sessions exploring these topics. Open to all ProMat attendees free of charge, the two educational sessions will occur in the Knowledge Center portion of the exhibit floor. Both focus on warehouse rack safety in traditional and e-commerce operations. Presenters will share the latest developments in current standards for the design, testing, and utilization of industrial steel storage racks. They will also answer questions in real-time.

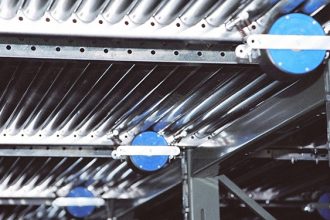

Storage Rack Safety Basics

The first seminar, “Storage Rack Safety 101,” occurs on Tuesday, March 21 from 3:00 – 3:45 p.m. Central time in Theater I on the show floor. Attendees will learn about RMI’s design and utilization resources that support greater warehouse rack safety. These include:

The first seminar, “Storage Rack Safety 101,” occurs on Tuesday, March 21 from 3:00 – 3:45 p.m. Central time in Theater I on the show floor. Attendees will learn about RMI’s design and utilization resources that support greater warehouse rack safety. These include:

- The ANSI MH16.1-2021 Specification for Design, Testing, and Utilization of Industrial Steel Storage Racks

- The ANSI MH16.3-2016 Specification for the Design, Testing, and Utilization of Industrial Steel Cantilevered Storage Racks

- The ANSI MH26.2-2017 Specification for the Design, Testing, and Utilization of Welded Wire Rack Decking

- Considerations for the Planning and Use of Industrial Steel Storage Racks

- Guideline for the Assessment and Repair or Replacement of Damaged Rack

Additionally, the session discusses the type and frequency of rack inspections that ensure warehouse rack safety. It will also cover rack accessories that offer protection from impacts. Finally, the discussion explores rack damage assessments and how to choose between repairing or replacing the damaged components.

Katie Ekstrand, Director of Inside Sales at RMI member Steel King Industries, and Brian Boals, Sales Manager for National Accounts at RMI member Ridg-U-Rak will present “Storage Rack Safety 101.” The duo said the material they’re covering is useful to owners and operators of both existing and planned warehouses.

“Because of its specific safety focus, directors of safety and human resources managers responsible for warehouse safety should also attend,” Boals noted. “We’ll share information about what is involved in maintaining and preventing damage to pallet rack systems, what to look for, and why each point is important.”

Ekstrand added, “Being proactive is essential to ensuring warehouse rack safety. Session attendees will gain useful knowledge on how to implement a proactive rack safety program that incorporates safe rack interactions, damage inspections, and repair and replacement processes.”

Tips for Rack System Planning

The second seminar, “Planning Your Rack System – Traditional and E-Commerce,” is on Wednesday, March 22 from 11:15 a.m. – 12:00 p.m. Central time in Theater H on the show floor. The presentation guides prospective and current users and owners of industrial storage racks through multiple rack styles and configurations. The session focuses on racking that meets the requirements of e-commerce and multi-channel retail operations. It explores important design considerations when determining which racking type will enhance warehouse rack safety in a given facility. Takeaways include the critical building blocks of a successful and safe pallet rack system design. Participants will also gain insights into current trends and changes in rack system design that meet e-commerce order fulfillment needs.

Presenters Jonathan Hirst, Vice President and General Manager of RMI member North American Storage Equipment, and John Schmidt, CEO of RMI member Rack Builders, noted that the material covered in this session will be informative and educational for persons involved in operations, planning, and safety.

“There are so many different types of storage rack systems. Each one has its own advantages, disadvantages, and unique aspects,” explained Schmidt. “Selecting the right rack system for an operation’s specific needs can have serious financial implications. Simply choosing the cheapest initial cost can result in huge expenses from operational inefficiencies, repairs, and overhead.”

Hirst agreed. “Product workflow through a facility is optimized when paired with specific racking systems based on a number of important factors,” he added. “As market demands change — such as the recent growth in e-commerce — this presentation may provide new ideas to operations faced with increased pressures to retrofit a traditional pallet picking operation into a more flexible, market ready omni-channel carton/manual picking operation.”

Those who are unable to attend the RMI sessions in person may still access the presentations and their accompanying audio via recordings that will be available online after ProMat concludes. Registration for the entire event — including all education seminars — is free.

Looking for answers to industrial storage rack system safety questions prior to ProMat? Visit RMI’s page of frequently asked questions (FAQs).