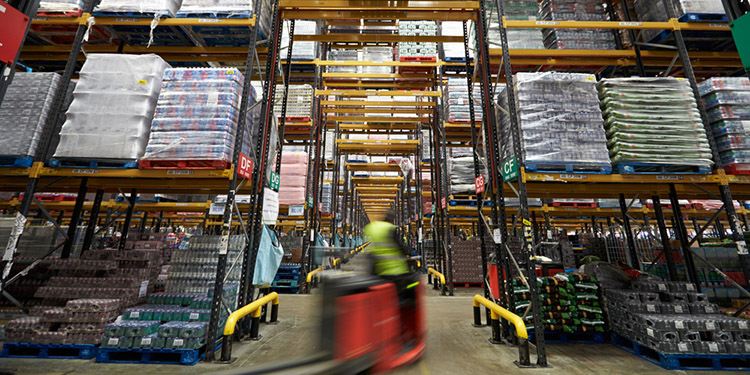

Drive-in rack and drive-through rack both provide high-density pallet storage with fewer aisles. Comprised primarily of vertical upright frames, horizontal support arms, and horizontal load rails—both typically handle for one-wide by multiple-depth storage. In a drive-in configuration, all loading and unloading happen from the same aisle. Conversely, drive-through rack is open at both ends of a bay. This permits material handling equipment to enter and exit from either end. However, because operators load and unload pallets of products inside both of these racking structures, rack safety measures are paramount. That’s because the risk of an unsafe situation caused by an impact to the rack structure is higher than witih other types of storage rack.

Rack Safety Best Practices for Drive-In and Drive-Through Systems

Here are four rack safety best practices to maintain the integrity of both drive-in and drive-through racking systems and safeguard operators:

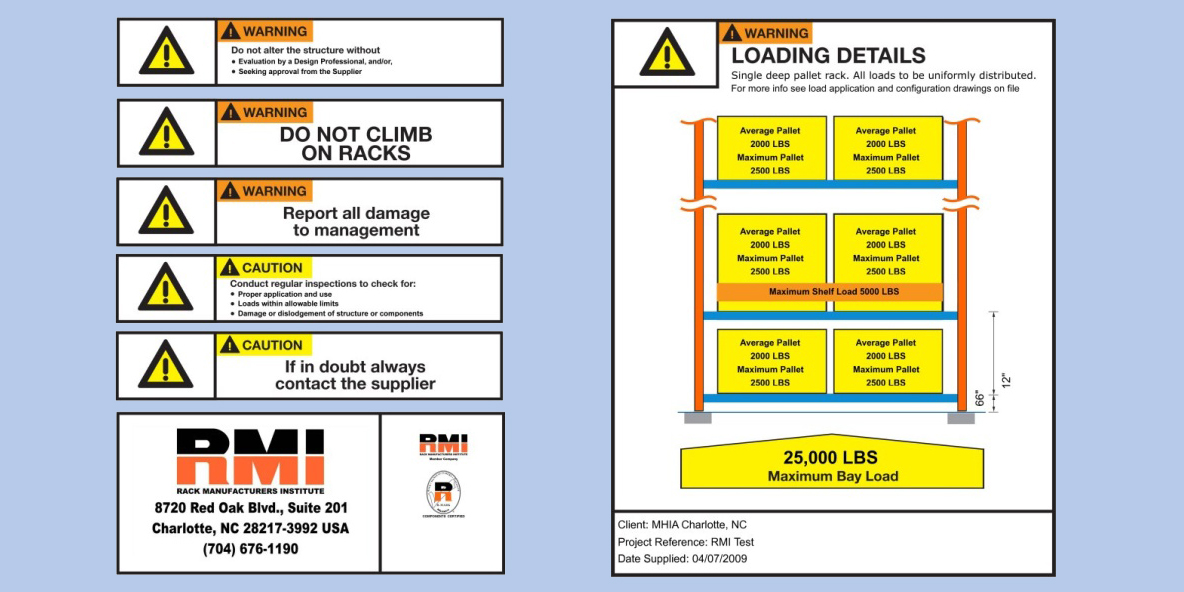

1. Design and engineer the system to the proper storage configuration and capacity.

To ensure the safest system, a qualified professional engineer should design the racking structure. The engineer should have experience creating rack structures—including drive-in and drive-through—that match the stored loads’ specifications. The engineer should also use the applicable guidelines in RMI’s ANSI MH16.1: Design, Testing and Utilization of Industrial Steel Storage Racks. Because of the openings within these racking systems, there may be special design or structural considerations made for installations in regions that are more prone to seismic activity.

2. Implement a comprehensive material handling equipment operator safety training program.

Forklift operator training with respect to navigating within drive-in and drive-through rack should include awareness of potential impact points on both sides of the bay as well as overhead, and any maneuvering limitations. Additionally, due to the dense nature of these systems, the storage bays themselves tend to be darker than traditional selective rack systems. To compensate, the forklift should be outfitted with lighting attachments that illuminate the surroundings in order to help the operator maneuver within the system.

3. Use proper pallets.

Since pallets are supported only along their outer edges by the drive-in rails, it is essential to confirm that they have sufficient capacity. Also verify their engineering allows their use in a drive-in application. Because pallets are suspended between the two rails, to reduce the risk of pallet collapse, it is important to verify that they are not damaged or missing a bottom board.

4. Regularly inspect the storage system for damage.

Collisions with material handling equipment (such as forklifts) are the most common cause of structural failure in all racking systems. Because this equipment navigates within a drive-in or drive-through rack structure, the risk of an impact and subsequent creation of an unsafe situation is that much higher. System owners must perform regular inspections to ensure that damaged racks are not storing loads. They must also promptly make proper repairs in consultation with the rack supplier and a qualified, professional engineer as recommended by RMI’s publication “Guideline for the Assessment and Repair or Replacement of Damaged Rack – Version 1.”

Learn More

Thinking of installing a drive-in or drive-through rack system? Find insights and comparisons to other rack-based storage types in RMI’s publication, “Considerations for the Planning and Use of Industrial Steel Storage Racks.”