New Employee Training: Teaching The Basics Of Rack Safety

According to 2021 data from the U.S. Bureau of Labor Statistics (BLS), the average rate of recorded injuries among warehousing employees was 5.5 for every 100 full-time workers. That represented an increase of 23% (122,700 cases) of days away from ...

Learn The Basics Of How To Specify Pallet Rack

Regardless of the type of industrial steel storage rack you’re shopping for—selective, drive-in, pushback, pallet flow, cantilevered, drive-thru, dual-bay, work platforms and any other related system—you’ll need to provide several important details to the rack manufacturer. Section 2 of RMI’s ...

How Picker Ergonomics Is Improved By Utilizing Pallet Separators In ...

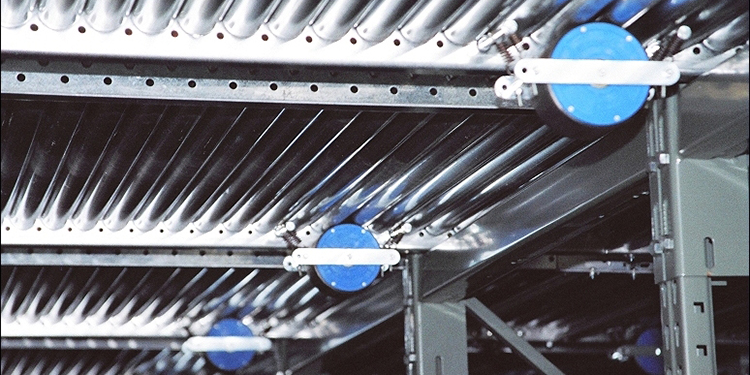

Engineered to hold multiple pallet loads in individual lanes pitched downward, high-density pallet flow (or “gravity flow”) rack is frequently used in case-picking operations. In these systems, full pallets of product are loaded from the back (or “charging”) end and ...

Jammed Pallet Flow System? Follow These Best Practices To Safely ...

Pallet hang-ups can happen in even the best maintained, properly loaded pallet flow rack system (also known as “gravity flow”). Jams can be caused by a variety of reasons, including a pallet that’s settled onto the tracks, debris in the ...

The “Dos and Don’ts” Of Pallet Flow Rack

Whether you own a pallet flow rack system (also referred to as “gravity flow” rack), or are considering investing in one, ownership comes with a variety of responsibilities. These include ensuring that the structure complies with applicable standards and is ...

How A Material Handling Specialist Can Help Create The Safest ...

While some organizations have in-house expertise and can determine the specification requirements and layout for a new storage rack without outside assistance, others who lack this skillset should consider engaging a material handling specialist to assist with this process. This ...

Planning A New Storage Rack Project? Answer These Questions For ...

Thinking of installing a new industrial steel storage rack? Whether the structure is intended for an existing facility or a new building, it’s important to be prepared to answer a series of questions and provide detailed information to the professional ...

Safe Approaches To Unjamming Pallet Flow Systems

Although its designed for the pallets stored within it to flow smoothly from the point of loading (also called “charging”) to the pick face, sometimes a jam occurs in pallet flow rack (also known as “gravity flow”). Whether it’s a ...

Why Pallet Flow Systems Are Designed For Specific Pallets And ...

The vast majority of industrial steel storage rack systems—including pallet flow (or “gravity flow”) rack—are engineered specifically for a single storage purpose. Likewise, when designing a high-density pallet flow system, there are a number of variables that must be taken ...

Applying Pallet Separators, Speed Controllers To Flow Rack

Because high-density pallet flow (also called “gravity flow”) rack is engineered to hold multiple pallet loads in a lane with a downward pitch, they are increasingly popular for use in case-picking operations. Full pallets are loaded from the back, or ...