The vast majority of industrial steel storage rack systems—including pallet flow (or “gravity flow”) rack—are engineered specifically for a single storage purpose. Likewise, when designing a high-density pallet flow system, an engineer must consider a number of variables to ensure its safety, structural integrity, and smooth operation.

Two of the most critical variables are the load itself and the type of pallet it rests on.

Assessing The Load

In order to design a rack system with adequate capacity to handle a given load, the design engineer must know the weights and dimensions of the individual loads intended for the system.

The weight of the load impacts the type of pallet flow used (full roller, split roller, skate wheel and more), its pitch, and the beams used. Further, the depth, width, and height of the load (or of the largest load if there are multiple types) must also be known. That’s because the overall capacity of the rack frame is determined by the vertical distance between shelf beams (which brace the structure), the weight of the loads placed on the beams, and the weight of the flow lane tracks.

When calculating beam spacing, the designer typically adds 12 inches to the height of the load. Six inches account for pallet height. Another six inches cover the clearance space necessary for a forklift to place or remove the load from the entry or exit point.

The beams act as upright supports. Therefore, the tighter the beam spacing, the denser the design and the stronger the rack bay. If the operation plans to store different types of loads within the same system, the entire structure’s design must accommodate the heaviest load. This ensures safe operation and minimizes the risk of collapse.

Assessing the Pallet

As the point of contact between load and the rollers or skate wheels, the pallet is also a critical element of pallet flow system design. Type, dimension, and orientation of the pallets used in a system can have a significant impact.

- Type means the material used in the pallet’s construction (wood, plastic, metal, or resin). Each material has its own unique set of properties. These characteristics could impact the ease with which the pallets flow down a lane. Pallet material type guides the decision about the style of flow tracks used (roller or wheel) to facilitate smooth operation.

- Dimension is the length and width of the pallet. This determines the number that can fit within a given lane. It also informs the number of lanes a building can accommodate.

- Orientation refers to the construction and configuration of the pallet’s underside. For smoothest operation and the lowest risk of a hang up within the system, it is optimal to place pallets in a lane with the bottom boards running parallel to the direction of the flow. However, pallets work in both directions. Therefore, it might be more space efficient to design the system with the bottom boards running perpendicular to the flow. Additionally, the rack design engineer must consider the quality, number and thickness of the bottom boards—as well as the shape and orientation of the undersides or feet of certain plastic or metal pallets. These characteristics can also impact flow performance.

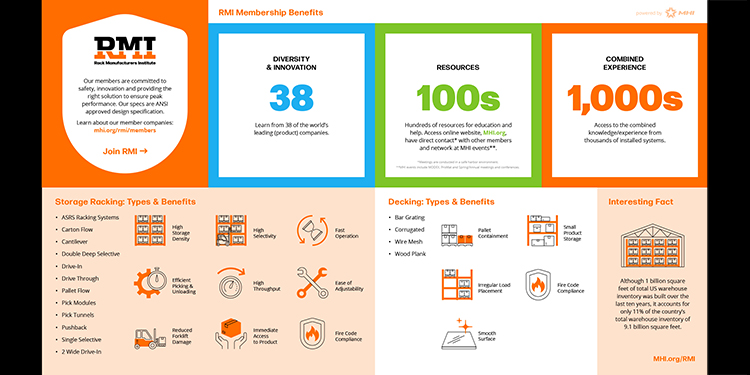

Looking for more information on how to pick the optimal pallet rack system for your operation? RMI will be presenting “Warehouse Racking Systems for the E-Commerce World,” at ProMat 2019.