In warehouse and distribution operations, pallet rack systems are mission-critical infrastructure. Yet, they also operate under significant physical stress. Failures can result in severe safety incidents and operational disruptions. Therefore—to help rack buyers mitigate these risks by ensuring that the racking they specify, install, and use meets the highest structural and safety standards—the Rack Manufacturers Institute (RMI) created the R-Mark certification program.

It’s important to understand that the R-Mark® is more than just a logo, noted Patrick Davison, Director of Standards at MHI. “R-Mark certification indicates that a storage rack manufacturer has demonstrated that they can manufacture, design, and install a storage rack system that complies with American National Standards Institute (ANSI) standards,” he said.

It’s important to understand that the R-Mark® is more than just a logo, noted Patrick Davison, Director of Standards at MHI. “R-Mark certification indicates that a storage rack manufacturer has demonstrated that they can manufacture, design, and install a storage rack system that complies with American National Standards Institute (ANSI) standards,” he said.

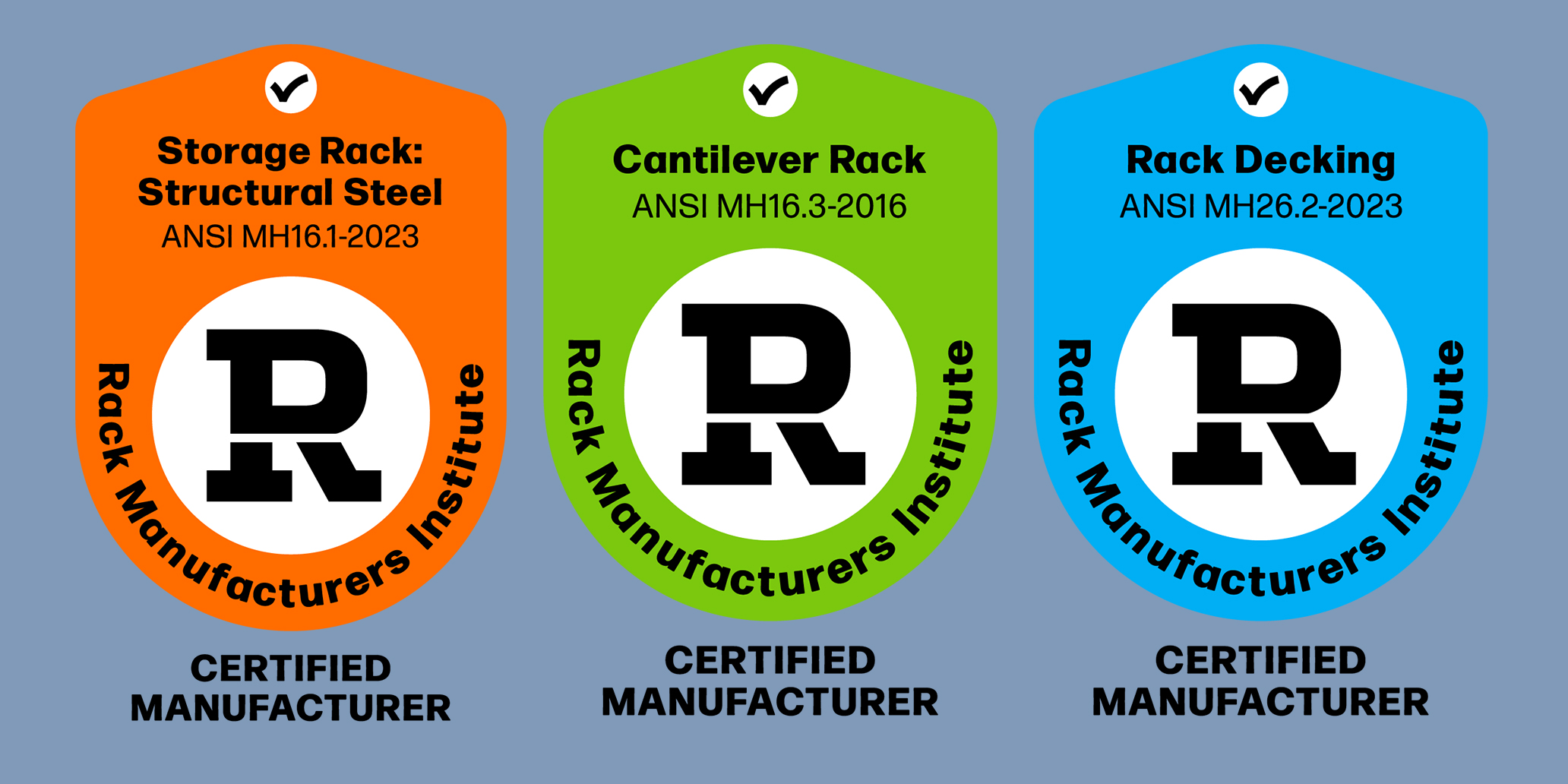

Specifically, certification indicates that a manufacturer complies with:

- ANSI MH16.1: Design, Testing, and Utilization of Industrial Steel Storage Racks, referenced by the International Building Code (IBC) as the standard for safe design and installation of steel storage racks.

- ANSI MH16.3: Design, Testing, and Utilization of Industrial Steel Cantilevered Storage Racks

- ANSI MH26.2: Design, Testing, and Utilization of Industrial Steel Rack Decking

“Ultimately, R-Mark certification reinforces claims of quality, defined as a system’s ability to fulfill its intended purpose,” Davison continued. “Any certification program is an attempt to bolster a manufacturer’s claims pertaining to quality. The R-Mark does that in the context of engineered storage rack systems.”

The R-Mark Certification Program

Davison emphasized that RMI’s certification program is voluntary. To qualify, manufacturers must submit sample designs for independent engineering review. “Companies awarded certification proved their ability to design, fabricate, and supply systems that conform to applicable RMI standards,” he said.

Initially introduced in the 1990s, the program has evolved into a multi-tiered structure, offering increasing levels of assurance:

1. R-Mark Certified Manufacturer

Indicates the company has demonstrated capability to produce rack systems that comply with RMI’s applicable ANSI standards.

2. R-Mark Certified System

Applies to specific system designs that meet current engineering standards and include approved Load Application and Rack Configuration (LARC) drawings.

3. R-Mark Certified Installation

Confirms that the installed system matches the certified system design, based on an on-site inspection by the manufacturer or its designated representative.

“This structure improves clarity around certification claims,” added Davison. “It also reinforces compliance at every stage—design, fabrication, and installation.”

System-Level Certification vs. Components

The R-Mark applies to complete rack systems, not individual components. This distinction reflects the fact that the configuration and installation of the components influences the rack’s overall system performance.

As Davison explained, “So much of the strength or performance characteristics of a storage rack depend on its proper design and installation. It’s like a giant Erector set—built correctly, it’s strong and stable. Built incorrectly, it’s vulnerable to failure.”

The one exception is rack decking, he added. “Decking is covered under its own ANSI standard (MH26.2) and therefore subject to separate certification criteria.”

Improvements to the R-Mark Program

After launching the R-Mark program nearly three decades ago, RMI recently made updates to the certification. These changes added important mechanisms for accountability and ongoing compliance, noted Davison. They include:

- Annual Attestation: Each certified manufacturer must confirm annually that no significant changes have occurred in their product lines or design processes that would affect compliance.

- Re-Certification with Updated Standards: When ANSI standard revisions occur, manufacturers must demonstrate that current products conform to the new provisions.

- Revocation and Reinstatement: RMI can revoke certifications for noncompliance. However, the certification can be reinstated after the manufacturer takes corrective measures—without restarting the full certification process.

These improvements address previous gaps where certifications could remain unchanged for years, even after significant product or standard updates.

Industry Impact and Trust

Notably, the R-Mark helps establish a baseline of trust throughout the supply chain, Davison stressed. That benefits not only manufacturers, but also facility owners, integrators, and regulatory officials.

For example, local building inspectors can use the R-Mark as an indicator that a rack system has been reviewed by engineers and meets applicable codes. This could potentially streamline the approval process. Practitioners can also gain increased confidence that the racking system is structurally sound. This reduces the need for ad hoc verification and inspections.

Davison drew a comparison to certification marks found on electrical equipment. “Just as the UL Mark indicates compliance with electrical codes, the R-Mark signals that a rack system has been engineered and verified as meeting national standards for structural safety,” he said.

Find an R-Mark Certified Manufacturer

The R-Mark Certification program provides a structured, transparent, and standards-based method for verifying the structural integrity of industrial steel storage racks. By evaluating manufacturers, system designs, and installations, the program reinforces engineering accountability and helps prevent avoidable failures in demanding environments.

“As supply chains grow more complex, the value of third-party certification becomes even more critical,” Davison concluded. “The R-Mark ensures that industrial storage rack systems meet recognized benchmarks—not just once, but throughout their lifecycle.”

For more information, including a list of R-Mark certified manufacturers, visit the RMI website.