What’s The Difference Between Pick Modules And Rack Supported Platforms?

Many warehouses today have a goal of doing all they can in their existing space — a sometimes difficult objective in an era of rapid expansion. In most cases, this comes down to maximizing their facility’s cube, either for increased throughput or higher capacity. This can mean building storage racking higher. It can also mean leveraging existing rack structures and converting them to pick modules or rack supported platforms. But how does an operation determine which option best fits its storage and handling needs? And what’s the difference between pick modules and rack supported platforms?

Picking Between Pick Modules and Rack Supported Platforms

The type of operations and processes that occur in the building dictate which type of system is ideal, said Aaron Conway, President of Mezzanine Safeti-Gates, a member of the Protective Guarding Manufacturers Association (ProGMA).

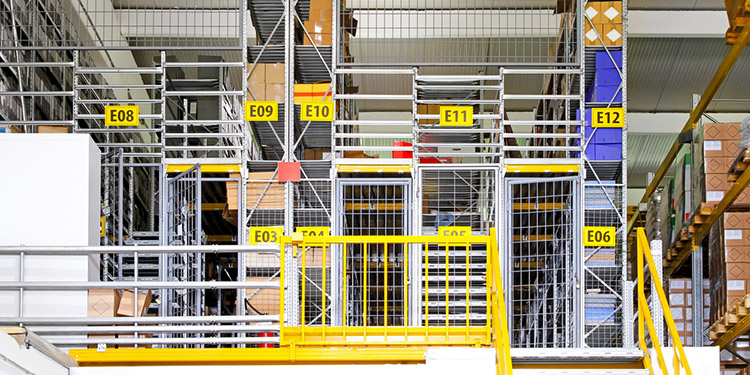

“A rack supported platform usually supports product storage, and sometimes assembly processes. Essentially, it’s like a mezzanine, but made out of pallet racking. It’s constructed from rack uprights and beams with flooring added to the higher levels,” Conway explained. “Rack supported platforms allow workers to both store and retrieve products with ease from the higher reaches of the structure. Associates must climb a set of stairs to reach that platform.”

Pick modules are a variation on rack supported platforms, he continued. Their installation typically supports workflows associated with order fulfillment.

“In pick modules, pallets of products are stored up high and accessed from a platform for picking. Employees break down pallets into smaller quantities by picking directly inside the racks. They then send the case picks to outbound shipping via a conveyor,” Conway said, adding that some pick modules also incorporate automated picking. “Automation can allow the operation to extend several levels high.”

Safety is Paramount

Regardless of which structure best suits an operation, both pick modules and rack supported platforms require safety measures. Therefore, the Rack Manufacturers Institute (RMI) includes design and configuration requirements for both in ANSI MH16.1: Design, Testing and Utilization of Industrial Steel Storage Racks, section 12.3.

Without the right protective guarding in place, pick modules and elevated work platforms can be dangerous places to work. Falls pose the biggest risk. This is particularly true if pickers are situated near the ledges. Fortunately, there are several protective guarding solutions available to enhance associate safety while working at heights, noted Conway. They include:

Guardrails

Specifically designed for integration around elevated work areas, guardrails (also sometimes referred to as guarding) prevent associates from falling over the edge. They surround the perimeter of the platform or walkway. Guidelines for their safe design and installation are in ANSI MH16.1. Also, ANSI MH.32-1: Stairs, Ladders, and Open-Edge Guards for Use with Material Handling Structures (section 5) — developed by RMI in partnership with the Storage Manufacturers Association (SMA) — offers safe guardrail guidelines.

Both standards say guardrails must consist of a top rail, an intermediate rail, and posts. The horizontal top rail must be at a minimum height of 42 inches above the floor surface. Further, intermediate rails must prevent a 21-inch-diameter sphere from passing through openings. For additional safety, the entire guardrail assembly’s design must resist a 200-pound concentrated live load force, or a 20-pounds-per-foot distributed live load force.

Kickplates

Also called toe boards or toe guards, these panels extend upward at the edge of the pick module or rack supported platform. Their presence prevents loose items from falling or sliding over the ends. This protects workers at lower levels from the impact of a falling object. Typically made of solid steel, kickplates must extend a minimum of 3.5 inches above the floor surface. Additional requirements are in both ANSI MH16.1 and ANSI MH.32-1.

Safety Gates

There should always be flooring underneath any pallets that associates working on upper levels are accessing. Likewise, guarding should be present on the ledges behind these pallets. In these situations, a dual-gate or double-hung safety gate barrier provides protection against falls. These systems incorporate barriers on both the ledge and a few feet back from the ledge. Their interconnected design ensures that if one gate opens, the other closes, securing the opening. This ensures workers cannot approach the open ledge while pallets are delivered, staged, or picked. Attached to the rack uprights, the gates significantly reduce the risk of a fall. Safety gates also secure vertical lifts (an alternative to stairs) that raise and lower personnel and products to and from upper platforms.

Safe Flooring is a Must for Pick Modules and Rack Supported Platforms

Another issue to consider is the flooring used on pick module and rack supported platform surfaces. Floors can be plywood, corrugated metal, or engineered flooring panels. It’s important to select the right flooring for a specific application, as the wrong material can create another safety hazard. For example, wood floors can splinter or crack; corrugated metal is loud and has openings that items can fall through; and engineered surfaces may pose potential slip hazards. It’s also important to consider ergonomic fatigue associated with spending long hours standing on these surfaces. The more forgiving the floor, the more comfortable and productive employees will be.

“Regardless of which rack-based elevated work solution is chosen, it’s important to work with an expert to create the safest system possible,” concluded Conway. “Operations should work with the rack’s manufacturer, systems integrator, dealer, or distributor for expert advice. Also, the members of ProGMA and the members of RMI are always available to consult on ways to correctly design safe pick modules and rack supported platforms.”

Looking for more details about other structural components that protect workers on pick modules and rack supported platforms? Download a free copy of the RMI/SMA ANSI MH32.1: Stairs, Ladders, and Open-Edge Guards for Use with Material Handling Structures specification.