Because high-density pallet flow (also called “gravity flow”) rack holds multiple pallet loads in a lane with a downward pitch, they are increasingly popular for use in case-picking operations. However, because the pallets in the lane rest against each other, they generate a substantial amount of force on the pallet at the pick-face. Adding pallet separators and speed controllers help keep pickers safe.

How Pallet Flow Rack Works

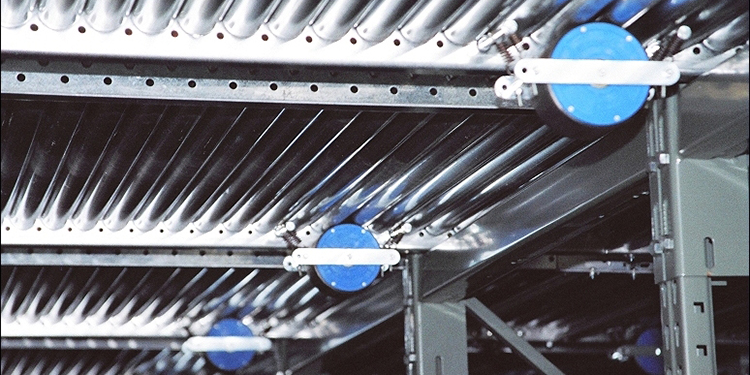

In pallet flow rack, a forklift loads full pallets from the back, or charging, end. The pallet rests atop a series of rollers or skate wheels in a lane. Gravity draws the pallets forward to the pick-face, or discharging, end. This allows pickers to split case pick from full pallets.

The force created from the loaded pallets is known as pallet flow back pressure. It measures approximately 6% of the full weight of all rear pallets.

3-deep system, 2,500 lb. load. Back pressure = .06 x 2,500 lbs. x 2 pallets = 300 lbs.

That increased force can make it extremely difficult for a picker to lift and remove the front pallet when empty. Attempting to do so has the potential for ergonomic injuries due to repetitive bending, stretching, and straining.

The Role of Pallet Separators

To mitigate pallet flow back pressure, the rack manufacturer can add a pallet separator to each lane. These are also known as a “hold-back” or “braking” devices. This interlocking component pops up above the roller or skate wheel tracks. It stops and holds the series of pallets behind the one at the pick-face, typically at a distance of 6 to 12 inches. That negates the forces that inhibit easy removal of the front pallet. To advance the pallet flow, an operator triggers a manual release latch. The release allows the next pallet to index into pick-face position.

When used in deep-lane flow, the device relieves the pressure otherwise experienced by the lift truck. That increases forklift driver productivity while preventing product damage as it eliminates the forces that prevent easy removal of the empty pallet.

Speed Controllers and Ramp Stops

For further control of pallet movement as each indexes forward in a lane, two other accessories can be added:

- Speed Controllers: Braking devices mounted below the roller tracks or dropped in on top of wheeled tracks—typically at a single pallet interval—that ensure pallets advance at a controlled, steady pace. In addition to minimizing the risk of product or pallet damage, the controllers help to keep the loads centered in the lane, reducing the risk of a hang-up.

- Ramp Stops: Also referred to as “end stops,” these devices are bolted onto the discharge end of the pallet flow rack lane and slow the advance of the first pallet, stopping it safely and holding it securely at the pick-face.

Learn More About Rack Safety

Looking for more storage rack safety guidelines? RMI will be presenting a free educational seminar, “Storage Rack Safety 101,” on Wednesday, April 10 at ProMat 2019 in Theater F at 11:15 a.m.